You are here: / Home

Filter Tests

INDUSTRIAL AND LABORATORY PRECIPITATORS

- Introduction

- Test of air filters for passenger compartments acc. DIN 71460, ISO 11155

- Test of Inlet air cleaning equipment for internal combustion engines and compressors acc. to ISO 5011

- Characterization of filter materials for surface/dedusting filters acc. VDI 3926 /DIN ISO 11057

- Classification of air filters for general ventilation acc. DIN EN ISO 16890

- Testing of vacuum cleaners acc. to DIN EN 60335-2-69 / IEC 60335-2-69

- Investigation of bag-, plate-, cartridge- and pocket filters

- Evaluation of separators for oil mist and cooling lubrications

- Filter media tests

- Petroleum hydrocarbons - track analytics

Introduction

To place their products on the market the producers of filter materials, filter elements and units for dust or droplet separation are dependent on the evaluation of their products.

The measurements are to carry out acc. to established rules and standards to ensure that the results of different institutions are based on the same test conditions as well as to the same measurement equipment.

At the Institute of Air Handling and Refrigeration, the tests and test rigs listed in the table of contents are available.

We would like to realize tests for you acc. to the called rules and standards. Futhermore we can help you with our measuring equipment, our test rigs and our experience to investigate and to optimize your filter elements, your droplet separators or electrostatic filters with practical aerosols like soot, dusts, oils, salt aerosols and fibers.

Test of air filters for passenger compartments acc. DIN 71460, ISO 11155

CONTACT:

- Dipl.-Ing. Martin Lauer | T +49 351 4081 5377 | email

- Dipl.-Ing. Stefan Holfeld | T +49 351 4081 5374 | email

SERVICE SPECTRUM:

- check acc. to DIN 71460, ISO 11155, DIN EN 15695-2, further on request

- filter tests acc. to customer specification

- material related investigations of filter medium and gasket material: temperature characteristics, weight per unit area, air permeability, burst resistance, tensile strength, elongation at break, compression hardness, compession set, combustion behavior, hydolysis resistance

TEST AIR CONDITIONING:

- air cleaning by HEPA filter and adsorption filter

- temperature range: 18...35°C

- range of humidity: 40...85 %

- volumetric flow range: 20...1600 m³/h

DETERMINATION OF:

- filter pressure loss

- adsorption behavior

- particle filtration efficiency / fractional filtration efficiency

AEROSOL GENERATION:

- droplet aerosols of different classes of size, concentrations and amounts, also monodisperse aerosols (Sinclair-La Mer-process or latex-standards)

- test dusts, also fibre-containing dusts or pure fibres

- soot generation by solid matter dispersion or controlled combustion

PARTICLE MEASUREMENT:

- single particle measurement (several particle counters: 0.1....10μm)

- dust / aerosol measurement with various light scattering spectrometers, by measurement of the aerodynamic diameter (0.5...20μm) or with mobility spectrometers SMPS /EEPS (5....950nm mobility diameter)

- dust concentration with beta dustmeter

TEST GAS FEEDING:

- feeding and evaporation of liquids (n-Butan, Cyclo-Hexan, n-Hexan, Toluol, others on request)

- feeding of several test gases (SO2, NO, NO2; H2S, NH3, others on request)

GAS ANALYSIS:

- total carbon concentration (flame ionisation detector, measuring range: 0.5....10,000 ppm)

- sulphur dioxide (fluerescence spectroscopy, measuring range: 1...20ppm)

- sulphur hydrocen (flourescence spectroscopy after conservation to sulphur dioxide, measuring range: 1...20ppm)

- nitrogen oxides (chemical luminescence detection, measuring range: 0...500ppm)

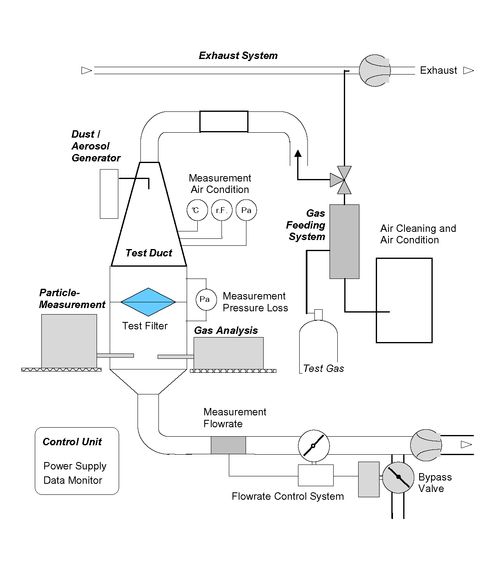

TEST RIG SCHEME:

Test of Inlet air cleaning equipment for internal combustion engines and compressors acc. to ISO 5011

CONTACT:

- Dipl.-Ing. Stefan Holfeld | T +49 351 4081 5374 | email

- Dipl.-Ing. Martin Lauer | T +49 351 4081 5377 | email

SERVICE SPECTRUM:

- test and characterisation of filtration systems, filter elements and air cleaning materials acc. to ISO 5011

TEST AIR CONDITIONING:

- air cleaning by HEPA filter and adsorption filter

- temperature range: 18...25°C

- range of humidity: 50...60 %

- volumentric flow range: 20...1500 m³/h

DETERMINATION OF:

- filter pressure loss

- particle filtration efficiency

DUST METERING AND DISPERSION:

- test dust AC Fine, AC Coarse, AC Ultrafine, Ashrae, Pural NF, soot

- concentration: 1 g/m³ (ISO 5011) or according customer requirements

PARTICLE MEASUREMENT - DETERMINATION OF SEPARATION EFFICIENCY:

- gravimetric determination by using an absolut filter

- measurement of fractional filtration efficiency by aerosol spectroscopy

Characterization of filter materials for surface/dedusting filters acc. VDI 3926 /DIN ISO 11057

CONTACT:

- Dipl.-Ing. Stefan Holfeld | T +49 351 4081 5374 | email

- Dr.-Ing. Liliana Kotte | T +49 351 4081 5376 | email

SERVICE SPECTRUM:

- test and characterization of filter materials for surface/dedusting filters acc. to VDI 3926, type 1 / DIN ISO 11057

- test and charakterization of filter materials as applicability test acc. to requirements of client

TEST AIR CONDITIONING:

- ambient air

- temperature range: 17...23°C

- range of humidity: 30...60 %

- constant filter area load: 120 m³/(m²/h)

DETERMINATION OF:

- filter test with aging acc. VDI 3926 / DIN ISO 11057 at ambient conditions

- other filter material tests as applicability test

- at variable conditions (filter area loading, dedusting conditions)

- with different dusts and

- free selectable filtration cycles for the purpose of aging

- investigations of customer-specific filter aids and adsorbents

PARTICLE MEASUREMENT:

- gravimetric determination of clean gas concentration

Classification of air filters for general ventilation acc. DIN EN ISO 16890

CONTACT:

- Dipl.-Ing. Martin Lauer | T +49 351 4081 5377 | email

- Dipl.-Ing. Stefan Holfeld | T +49 351 4081 5374 | email

Testing of particulate air filters for general ventilation acc. to DIN EN ISO 16890, EN 779 or ANSI/ ASHRAE Standard 52.2

SERVICE SPECTRUM:

- test of pressure loss, separation and dust accumulation behavior of particulate air filters for general ventilation acc. to international standards

- test and classification of particulate air filters in the filter classes ISO coarse, ISO ePM10, ISO ePM2.5 and ISO ePM1 acc. to ISO 16890 / test with Arizona fine dust and DEHS / KCl aerosols

- conditioning with isopropanol vapour acc. ISO 16890-4

- test acc. to former standard EN 779 still possible, classification from G1 to G4 (coarse filters), M5 to M6 (medium filters) and F7 to F9 (fine filters) / test with ASHRAE 52.1 test dust and DEHS aerosol

- test and classification of particulate air filters in the filter classes MERV1 to MERV16 acc. to ANSI/ ASHRAE STANDARD 52.2 / test with ASHRAE 52.1 test dust and KCl aerosol

- test report in German and/or English language

TEST CONDITIONS:

- free flow cross-section 610 mm x 610 mm

- indoor air or ambient air, prefiltered by filtration stages with air-, charcoal- and HEPA-filter

- volumetric flow range: 850 m³h-1 (0.236 m³s-1) to 4500 m³h-1(1.25 m³s-1)

- final pressure loss: max. 1000 Pa

- dust concentration: 70 mgm-3 to 140 mgm-3

DUST AND AEROSOL DISPENSION:

- dust generator: ASHRAE Dust Disperser SAG440, Topas GmbH

- aerosol generator: DEHS - ATM 225 for DEHS, Topas GmbH

- Aerosol generator: KCl - LPAG 8108, TSI Inc.

DUST AND AEROSOL MEASUREMENT:

- dust measurement:gravimetric by absolute filter method or with plane filter sampling unit, Paul Gothe GmbH

- aerosol measurement:laser optical aerosol spectrometer OPS 3330, TSI Inc.

Testing of vacuum cleaners acc. to DIN EN 60335-2-69 / IEC 60335-2-69

CONTACT:

- Dipl.-Ing. Dirk Keßlau | T +49 351 4081 5375 | email

- Dr.-Ing. Liliana Kotte | T +49 351 4041 5376 | email

CLASSIFICATION OF DUST CLASSES ACC. TO DIN EN 60335-2-69

Based upon their endangering potential dusts are attached to the dust classes L (light danger), M (mean danger) and H (high danger). Table 1 shows that increasing demands are made on industrial vacuum cleaners and dedusters with increasing endangering potential of the aspirated dusts. The applicability of the suction apparatus is to account for the respective application field by standardised test.

| Dust Class | Applicability for dangerous dust with critical value at commercial exposure [mg/m³] | Transmittance D [%] |

| L (light danger) | > 1,0 | < 1,0 |

| M (mean danger) | ≥ 0,1 | <0,1 |

| H (high danger) | < 0,1 including cancerogenic dusts and dusts with cancerogenic particles with health risk | < 0,005 |

A comparing description of classifying od dedusting machines can be found on the pages of the german Institute für Arbeitsschutz (IFA)

SERVICE SPECTRUM:

- Test acc. to DIN EN 60335-2-69

- 22.AA.201.1 Filter Material Test

- 22.AA.201.2 Essential Filter Element Test

- 22.AA.201.3 Assembled Machine Test

- 22.AA.201.4 Burst Strength Test

Your units like vacuum cleaner or deduster can be tested acc. to valid international test procedures at the Institut of Air Handling and Refrigeration (short: ILK). For the required measurements the test setup shown in the picture is available. At positive results you get a certificate.

TEST RIG:

Investigation of bag-, plate-, cartridge- and pocket filters

CONTACT:

- Dipl.-Ing. Ralf Heidenreich | T +49 351 4081 5360 | email

TEST RIG FOR INVESTIGATION OF BAG-, PLATE-, CARTRIDGE- AND POCKET FILTERS

The ILK Dresden possesses a flexible, vertical test rig for the testing of cartridge filters, hose filters, filter bags and filter plates with a length up to 6 m. The raw gas volume can be adapted to the demand in 1.5 meter steps to the total height of 6 m because of ist modular design.

SERVICE SPECTRUM:

- performance measurement on a filter elements test rig with pressurized air regeneration in continuation of German technical rules VDI 3677/VDI 3926/DIN 11057

- determination of the pressure, energetic and separating behavior of filter elements

- performance comparison of filter elements at defined amd reproducible test conditions

TEST CONDITIONS:

- up to five installed filter elements

- design of the compressed air regeneration system and Adaption to the filter element

- intensive regeneration and single regeneration

- standard operation or operation adapted

- several test dusts

- dust mass flow: variable

- impulse time: variable

- regeneration pressure: variable

TEST RESULTS:

- compressed air consumption per regeneration impulse

- mean compressed air consumption per filter element depending on dedusting mode

- specific energy consumption of filter elements regarding to air volume flow

- optimum operational behavior regarding to energy and separation behavior

- recommended filtration area loading

- separation behavior of filter elements for corresponding dusts

- gravimetric dust measurement of mean clean gas dust concentration (guarantee value)

- measurement of fractional filtration efficency by aerosol spectroscopy

Evaluation of separators for oil mist and cooling lubrications

CONTACT:

- Dipl.-Ing. Dirk Keßlau | T +49 351 4081 5375 | email

Oils and cooling lubrication agents are used for metal cutting and forming manufacturing processes. They are essentailly for the high quality of the machining of metals. The application of the cooling lubrication agent serves at first for the cooling of the tool as well as for friction reduction between tool and workpiece at the metal cutting or forming. The careless exposure can result in a sanitary danger for the staff that is engaged in this manufacturing process. Furthermore a loading of environment by air pollution or ground water endangering is possible.

Characteristic aerosols, smoke, mists and vapours orginate from mechanical or thermal processes. It is to ensure that these particle and gaseous pollutions are separated in terms of labour protection, air pollution control and quality assurance.

The ILK Dresden operates in the frame of its research activities a test field for the evaluation of separators for oil mist and cooling lubrication agents. The investigation of separators is carried out with the latest facilities and methods of aerosol mechanics and particle engineering from "nano" to "macro". The ILK Dresden can offer a long-standing experience in this matter.

SERVICE SPECTRUM:

- test and characterization of filter elements and other separation materials and installations for the separation of oil mists and cooling lubricant agents

- maximum installation size: 630 x 630 mm

TEST AIR CONDITIONING:

- ambient air

- temperature range: ca. 20...25°C

- range of relative air humidity: ca. 50%

- volumetric flow range: 750...4500 m³/h (dependent on pressure loss)

DETERMINATION OF:

- filter pressure loss

- loading behavior at aerosol metering

- total filtration efficiency (gravimetric)

- fractional filtration efficiency (relating to particle number or specific volume)

- filtration efficiency for the gas as well as vapour phase acc. to BIA procedure 3110

AEROSOL METERING:

- droplet aerosols in several size classes (nm up to μm range), concentrations and amounts

- custom-specific oils and lubricants

- heated metering for low-volatile oils / lubricants

PARTICLE MEASUREMENT:

- gravimetric determination or raw and clean gas concentration acc. to VDI 2066

- aerosol measurement with scattering spectrometer (laser) by measurement of the aerodynamic diameter (0.5...20 μm)

- aerosol measurement by electrostatic classifying with the SMPS system (16.5...680 nm mobility diameter)

- aerosol measurement by electrostatic classifying with the EEPS system (5...580 nm mobility diameter, 0.1 s cycle)

- monitoring of raw gas metering with scattering spectrometer

GAS AND VAPOUR ANALYSIS:

- total carbon content (flame ionisations detector, measuring range: 0.5...95,000 ppm)

- elution of test filter loaded with mineral oils with tetrachloroethylene

- evaluation with FT-IR spectroscopy

Filter media tests

CONTACT:

Dr.-Ing. Liliana Kotte | T +49 351 4081 5376 | email

SERVICE SPECTRUM:

- material aging by temperature

- bursting strenght acc. DIN EN ISO 2758

- Grammage acc. DIN EN ISO 536

- tensile properties acc. DIN EN ISO 1924-2

- permeability of fabrics acc. DIN EN ISO 9237

Petroleum hydrocarbons - track analytics

Your Request

Further Projects

Electrochemical decontamination of electrically conducting surfaces „EDeKo II“

Improvement of sanitary prevention by electrochemical decontamination