You are here: Home / Research and Development

Cryogenic liquid piston pumps for cold liquefied gases like LIN, LOX, LHe, LH2, LNG, LAr

Feeding pumps for cryogenic liquid gases

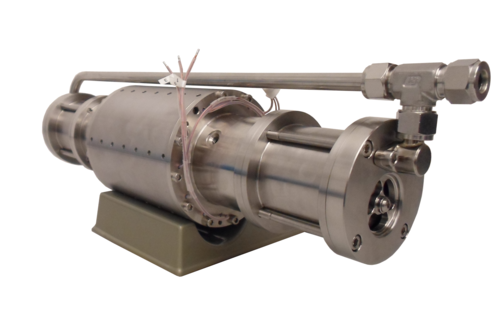

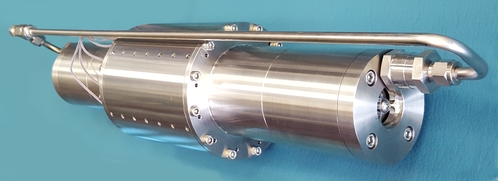

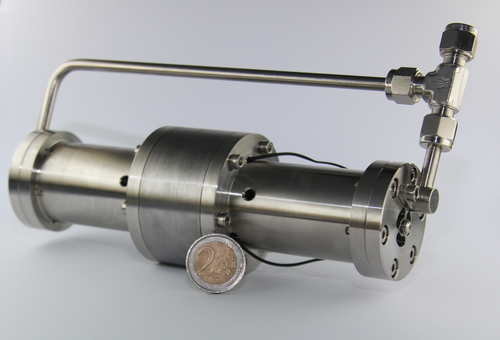

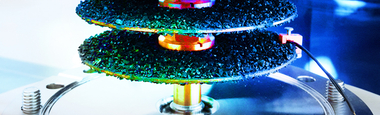

The ILK has developed a modularly constructed pump that can deliver cryogenic liquefied gases like LN2, LO2, LHe, LNG, LAr and others. Thanks to the building block principle tailor-made solutions can be offered by the combination of pump drives of different power categories together with geometrically optimized pump heads to satisfy the individual requirements of volume flow, pressure build-up and conveyed medium.

Designed as piston pump it is characterized by comparably slow stroke speeds. That low pace eliminates or reduces the tendency towards cavitation as flow resistances and accelerating forces are reduced to a minimum.

Owing to its special design and the material combinations used the linear drive can be operated at deep-cold temperatures. It is mounted between the cylinders of the piston pump and is immersed and submerged directly in the cryogenic liquid gas. By avoiding rotating parts a conventional lubrication with oil and grease becomes needless, this allows for an almost maintenance-free operation.

The pumping cylinders are arranged on both sides of the linear drive. The valves are integrated into the cylinder heads. For each application they are customized for the required flow capacity and the physical properties of the medium to be delivered (regarding density, viscosity and cavitation tendency).

The design as double-acting piston pump facilitates an extraordinary high dynamism of the delivered volume flow. The (constant) speed of the linear drive can be varied in a wide range to generate an even volume flow. An intermittent operation is easily possible and allows for a high pump efficiency even at partial-load situation close to zero. Adverse effects like increased heat input or limited start-stop-cycles do not occur.

Due to the easy possibility to immerse and submerge in the cryogenic liquid to be fed, the piston pump is excellently suited to e. g. circulate the cryogenic cooling liquid along a superconducting power line in a hermetic piping system. Another application can be found in the dispensing of cryogenic liquid into transport dewars as the pump eliminates the need of artificial evaporation of the medium for pressure build-up during filling.

Video Operation with Liquid Argon and Liquid Nitrogen

Granted Patent

DE 10 2008 011 456.1

Your Request

Further Projects - Research and Development

Influenced melting point of water by magnetic field

Controlled sub-cooling of products in freezing processes