You are here: / Home

Behavior of multiphase cryogenic fluids

experimental und numerical investigations

With the help of this basic research project, processes that occur during the sudden evaporation of cryogenic media should be better understood, described and evaluated. This should create possibilities for improved design and efficient operation of safety elements and power transmitting components in plants with cryogenic media.

A well-founded theoretical understanding of the dynamic calculation and evaluation of boiling cryogenic media will be developed. In order to obtain, for example, a concrete component behaviour under cryogenic conditions, numerical descriptions are required beyond the design calculations, both for fluid dynamics and for the spatial and temporal change in temperature.

Parallel to this, the experimental basis for the design of complex cryogenic components and systems engineering is being improved.

The objectives and results of the preliminary research project include

- Calculated parameters from various numerical simulations for essential cryogenic components

- Extensive experimental results for variations of the underlying geometry, advantageous process control, improved design of components

- Basic thermodynamic processes in gas chillers

- Calculation algorithms for the description of dynamic heat transport phenomena

- Evaluation of critical plant conditions

- Suitable materials for cryostat components and cryogenic plants

- Novel components e.g. for small helium mass flows

An application project for the development of heat exchangers for cryogenic multiphase fluids is planned.

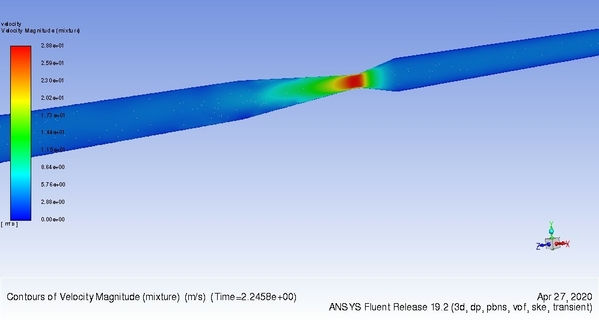

Video of the mass transfer rate between the liquid and the vapour phase inside a Venturi tube

If you can not see the video, please use the external link to YouTube.

Further Projects

Hydrogen and methane testing field at the ILK

Simultaneously pressures up to 1,000 bar, temperatures down to –253°C

Low noise and non metallic liquid-helium cryostat

Low-noise Magnetic Field Cryostat for SQUID-Applications

Cryostats, Non-Metallic and Metallic

position indenpendent, highest endurance, tiltable for liquid helium and liquid nitrogen

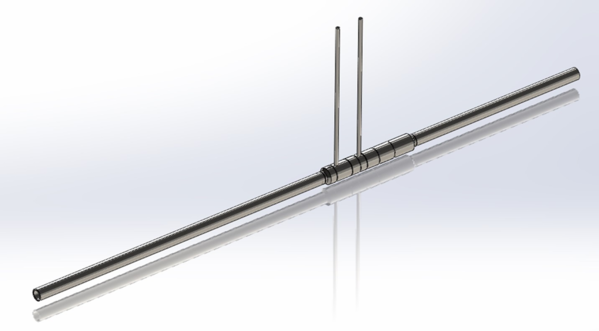

Cryogenic liquid piston pumps for cold liquefied gases like LIN, LOX, LHe, LH2, LNG, LAr

Feeding pumps for cryogenic liquid gases