You are here: / Home

Hybrid- Fluid for CO2-Sublimation Cycle

Cryogenic cooling by CO2 sublimation

The objective of the research project is the selection and qualification of a new refrigeration fluid. The so called “Hybrid-Fluid” should be used both as a lubricant for compressor lubrication and as a heat transfer fluid in a CO2 sublimator. Such a fluid is a requirement for the implementation of a closed low GWP CO2 sublimation refrigeration cycle. It could be used as a replacement for previous high-GWP cold steam refrigeration cycles in a temperature range down to -80 °C.

The project idea is based on the intension to find a fluid that combines the advantages of compressor lubrication and heat transfer in a sublimator. It has to be clarified which fluid fulfill these requirements best. It would be advantageous to use a fluid which has a good solubility for CO2 at low temperatures in order to achieve a lower viscosity for a better flow characteristic in the sublimator. In addition, the viscosity should allow sufficient lubrication of the compressor under CO2 compression. On the other hand, a fluid with low solubility of CO2 would not contribute to the improved viscosity reduction in the sublimator but would show advantages for lubrication of the compressor instead.

Areas of application for cooling temperatures below -50 °C are numerous. Examples include applications in the fields of environmental simulation, medical and pharmaceutical technology, cryopreservation, freeze-drying and food technology. Upon successful completion of the research project, an important prerequisite for operating closed sublimation refrigeration cycles will be created to replace R-23 with the environmentally friendly refrigerant CO2 in a range of different applications.

In the refrigeration market in the EU currently a shortage of fluorinated refrigerants with high global warming potential (GWP) values is observed. This goes along with rising prices which have already reached several hundred Euros per kilogram for the low temperature refrigerant R-23. No relief is expected since with the commencement of the EU F-Gas Regulation in 2015 emission reduction provisions have been made which are binding for the next decades. Thus, pressure on affected manufacturers is growing to look for replacement refrigerants for their applications. However, for cooling temperatures below -50 °C, there are currently no non-flammable refrigerant alternatives. The CO2 sublimation is a suitable way to realize cooling temperatures below -50 °C with a non-flammable refrigerant.

Your Request

Further Projects

Optimizing HVAC operation with machine learning

Intelligent control of HVAC systems – high comfort with low energy demand

Industry 4.0 membrane heat and mass exchanger (i-MWÜ4.0)

Linking the entire life cycle of a multi-functional air handling unit

Verification of storage suitability of cryo tubes

Artificial aging of primary packaging for biobanking applications

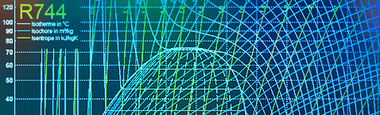

![[Translate to EN:] Abb. 1: Phasenzustandsdiagramm von Kohlendioxid mit dem vorgesehenen Temperaturarbeitsbereich (hellblau)](/fileadmin/user_upload/Artikel/2019/Hybrid-Fluid/CO2_Hybridfluid.png)