You are here: Home / Measurements and Tests

Lifetime prediction of hermetic compressor systems

Partial discharges in motor windings

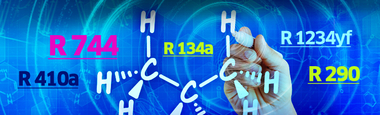

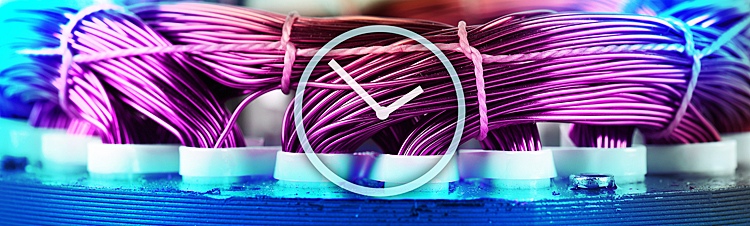

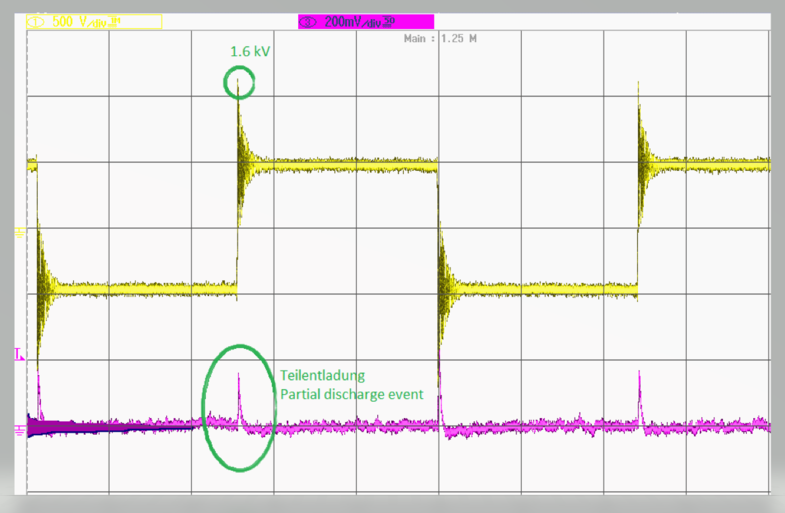

In the field of refrigeration and air conditioning technology, speed-controlled compressors are increasingly being used. In addition to stationary refrigeration, this also applies in particular to the automotive sector, where frequency converter-fed electric motors are being used for compressors in the course of the spread of e-mobility. The use of frequency converters is associated with a pulse-shaped voltage stress on the motor windings in the compressors. This results in an overshoot of the voltage (especially with longer motor cables), which leads to higher stress on the insulation compared to operation with sinusoidal voltage.

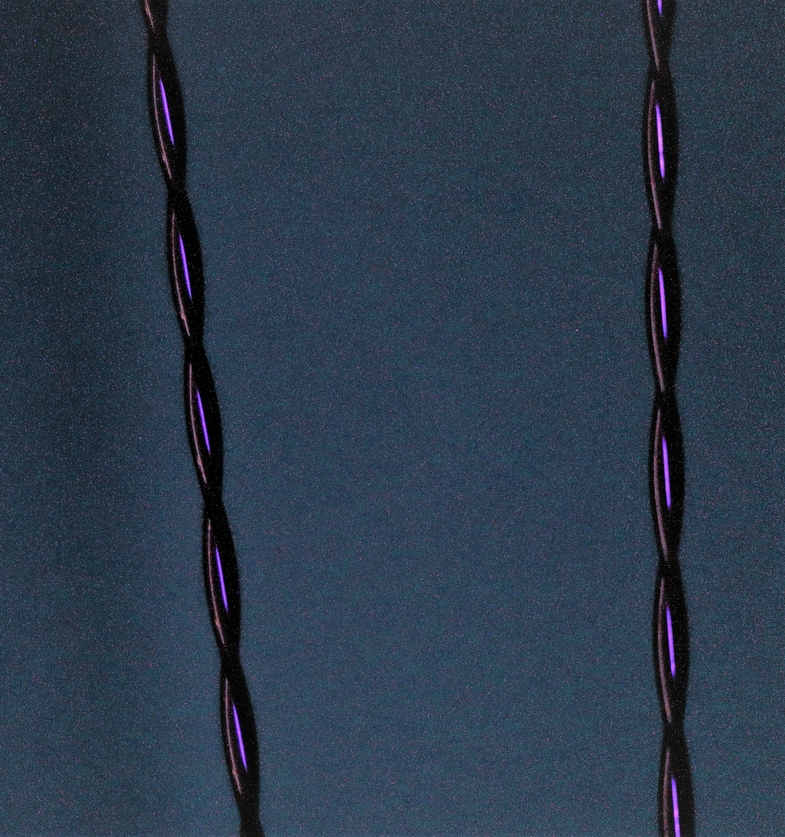

These pulses can lead to partial discharges (PD) on and in the insulation and represent a high stress for the insulation systems of the motor windings.

In addition to this electrical stress on the insulating materials, there are other influencing factors, particularly in refrigerant compressors, which cause the insulating system to age, especially thermal and chemical effects. For investigations on the winding insulations of refrigerant compressors, the chemical factors influencing aging should therefore be taken into account. These interactions significantly complicate the service life prediction for the winding insulation of refrigerant compressor motors.

The aim of the project is to develop test setups and procedures that will enable the evaluation and optimization of insulation systems for motor windings of refrigerant compressors with regard to service life during frequency converter operation.

The following problems are addressed in the project:

- How does the insulation system behave under pulse voltage in refrigerant-oil atmosphere (gas, pressure, temperature, water content, oil wetting, voltage parameters)?

- When do partial discharges occur in the stator under operating conditions (dependence on winding structure)?

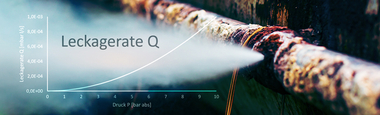

- Can the service life of the winding insulation be predicted based on time-lapse tests of wire windings, and if so, how?

- By what test method can the PD strength of flat wire insulation be assessed?

New test setups to be developed, a pulse generator and PD measurement technology are to be used to investigate the influence of the refrigerant and oil, the voltage parameters (voltage level, pulse length, frequency, edge steepness, polarity) on the partial discharge behavior and the service life of enameled wires and stators under refrigerant-oil atmosphere. Based on these investigations, a method for predicting the service life of motor insulation systems in terms of partial discharge resistance will be developed.

Your Request

Further Projects - Measurements and Tests

Tribological investigations of oil-refrigerant-material-systems

Modified Almen-Wieland wear testing machine

Investigation of materials

Investigations regarding the compatibility of materials with refrigerants, oils and heat transfer fluids