You are here: Home / Measurements and Tests

Testing of mobile leak detectors according to DIN EN 14624

Performance test according to standard

Determination of the performance of mobile leak detectors

According to Regulation (EU) No. 517/2014, systems containing fluorinated greenhouse gases must be tested for leaks at regular intervals (varying between 6 months and 2 years) depending on the CO2 equivalent. In practice, mobile leak detectors are mainly used for this purpose.

To ensure the proper functioning of the equipment, Regulation (EC) 1516/2007 requires that refrigeration and air conditioning equipment and heat pumps with a charge > 3 kg of fluorinated greenhouse gases be tested for proper operation every 12 months. "The sensitivity of portable gas detection devices must be at least 5 g per year".

According to DIN EN 378-2 section 6.3.3.2, the detector must be calibrated at regular intervals according to the manufacturer's instructions.

The test procedure for at least annual inspections of the performance of mobile leak detectors and room monitors for halogenated refrigerants is described in DIN EN 14624.

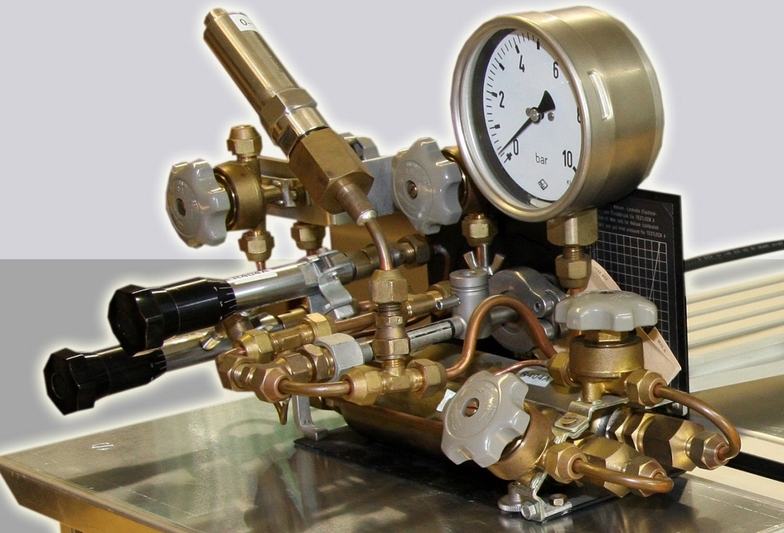

For this check, use, for example, a testing device with a sliding or swiveling leak detector probe. The performance test includes:

- static detection with detection limit

- Response time

- Cross sensitivity

- dynamic detection limit

- Detection limit with contaminated environment

- Recovery time

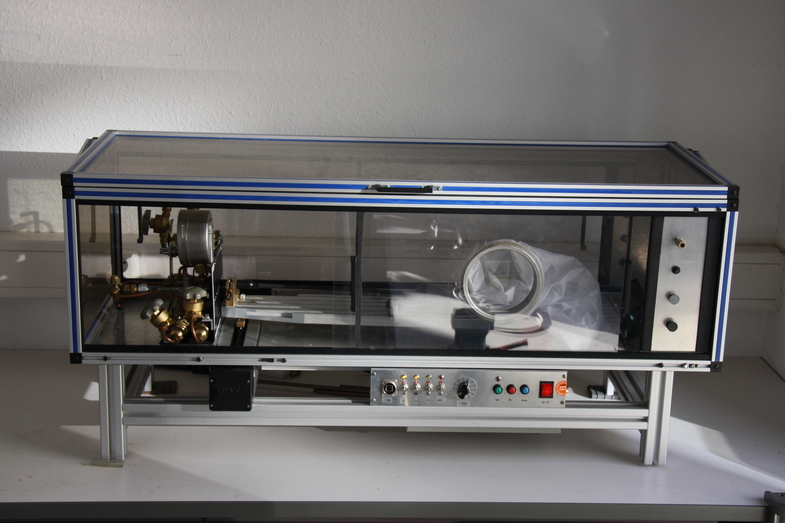

For these tests, a test stand is available at the ILK Dresden on which mobile leak detectors can be tested for their performance.

To determine the performance, adjustable calibrated test leaks are filled with the appropriate test gases (e.g. R134a, R1234yf) and placed in the test stand. We would be pleased to perform this test for you. The test performed is certified with a test report.

Please direct inquiries about testing mobile leak detectors with the appropriate test gases to the contact above.

Your Request

Further Projects - Measurements and Tests

Tribological investigations of oil-refrigerant-material-systems

Modified Almen-Wieland wear testing machine

Investigation of materials

Investigations regarding the compatibility of materials with refrigerants, oils and heat transfer fluids