You are here: Home / Measurements and Tests

Thermostatic Expansion Valves

Does the TXV function correctly?

We support the industry in the development of energy-efficient vapor-compression refrigeration system and compression heat pumps.

The ILK Dresden offers the following services for you:

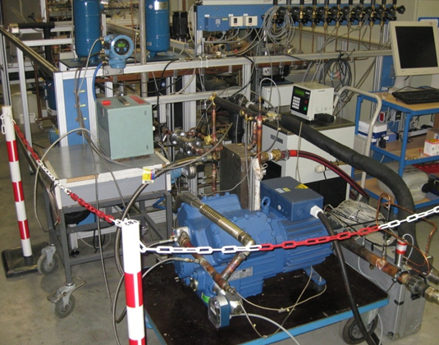

The ILK Dresden have been active in the field of performance testing of refrigeration compressors and condensing units for over 20 years.

Our offer includes also the investigation of thermostatic expansion valves (TEV) with external temperature sensors.

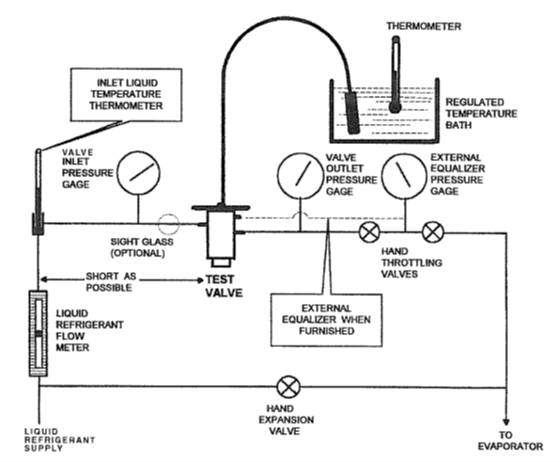

The tests of the TEV are carried out on a suitable refrigeration cycles (fig. 2), taking into account the following standards

- AHRI 750 (2007),

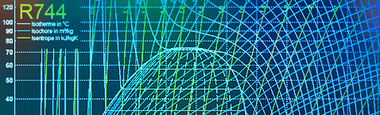

- ANSI/ ASHRAE 17 (2008, fig. 1) and

- ASERCOM-Statement (9_GER_Dimensionierung_von_TXV_2011)

Current calibrations of the measuring systems are a matter of course.

The test can be carried out with the refrigerants R134a, R404A, R407A, R407C, R407F, R448A, R513A, R452A up to a mass flow of 400 kg/h (~20 kW for R134a).

Additional offerings

The following influences on the valve behaviour can be investigated

- run-in period

- hysteresis

- transient tests / time constant

- pressure losses

- sub cooling

- ambient temperature

- critical pressure ratio