You are here: Home / Software Development

Software for test rigs

Individual software for complex tests and evaluation

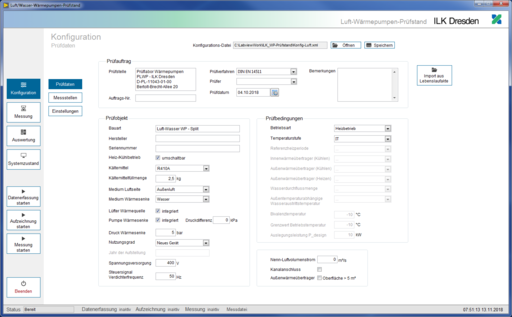

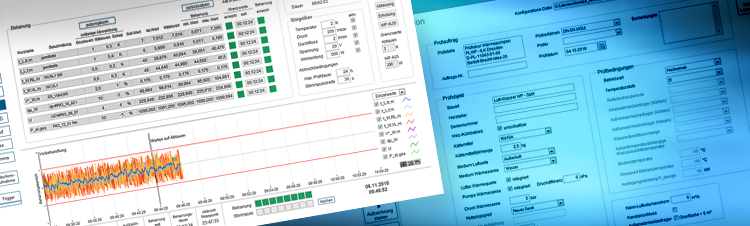

The ILK has many experiences in constructing test rigs and in testing compressors and other components of refrigeration cycles. With this knowledge, we offer our customers modular software for highly automated test rigs and the evaluation of the measured data. We use LabVIEW from National Instruments as development environment. The functions and the user interface of the software are adapted according to customer requirements and the standards for test rigs.

Test rig software

The software can exchange data with various measurement systems via Ethernet or serial interfaces. Standard protocols like OPC and Modbus as well as special protocols, e.g. for Yokogawa or Delphin instruments, are implemented. The transmitted data can be scaled, averaged and checked for validity in the software. Calculation channels for mathematical functions or substance properties can be added. If no measurement hardware is available, the software can output simulated values.

The measured values are stored in binary and compact TDMS files. Storage in SQL based databases is also possible. The software enables data export to Microsoft Excel for individual evaluation.

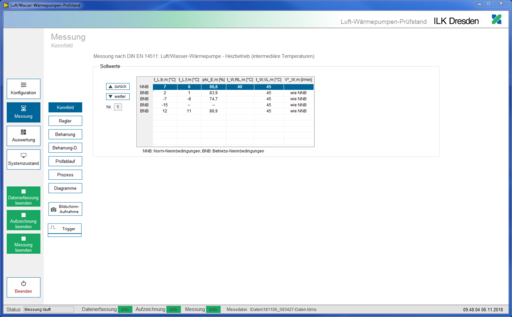

The user can input test information before the start of a measurement. These data are stored in the measurement file and determine the required test points. The user can modify these points subsequently or defines a new set point table.

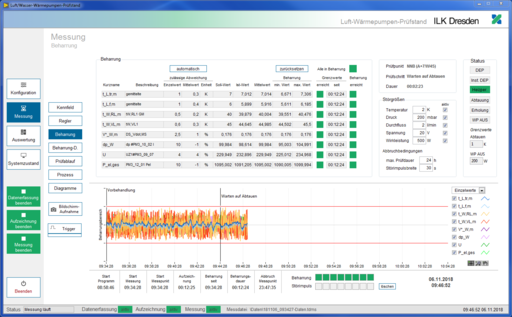

The software controls and monitors the test rig during the test. For controlling, it uses various control algorithms, which the user can parameterize. The software can also detect the steady state of selected variables.

In this way, complex test sequences like heat pump testing according to DIN EN 14511 can be implemented. Simultaneously the program can check the measurement values for compliance with defined limits and, if necessary, the program can switch to the next test point or turn off the test rig. All measured and controlled variables are displayed in time-based diagrams, tables and a simplified P&ID diagram. Once a test point has been successfully measured, the software can switch automatically to the next test point via a ramp, if required. After termination of the last test point, the measurement stops and the test rig is switched off.

Evaluation software

In addition to exporting the measured data to an Excel or text file, a complex and detailed evaluation of the measured test points can be carried out. For this purpose, we offer highly specialized and individual evaluation software. It handles measurement data from various test rigs, if the data format and structure is compatible and documented. In the software, existing test information can be edited, any measured values averaged, renamed and assigned to channels required by the standard. There is also the possibility to add channels for calculation or substance properties. Furthermore, the steady state of a measurement period can be checked again and, if necessary, test points can be accepted or rejected. Finally, the measured values of selected periods as well as the results of the test are transferred to Excel sheets, which are formatted according to the customer requirements. Protocols created in this way can be printed, processed or stored.

Your Request

Further Projects - Software Development

Optimizing HVAC operation with machine learning

Intelligent control of HVAC systems – high comfort with low energy demand

Software for technical building equipment

Design cooling load and energetic annual simulation (VDI 2078, VDI 6007, VDI 6020)