After ten years the Chillventa 2018 sets a real milestone once again with more than 1.000 exhibitors from all over the world. A new record of visitors was achieved with 35.490 guests.

„The Chillventa once again impressively emphasized its role as the refrigeration industry’s most important international hub for air conditioning, ventilation and heat pump technology“, says Daniela Heinkel, Conference Manager Chillventa, NürnbergMesse.

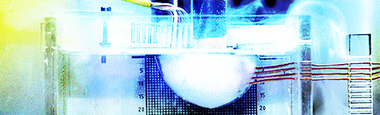

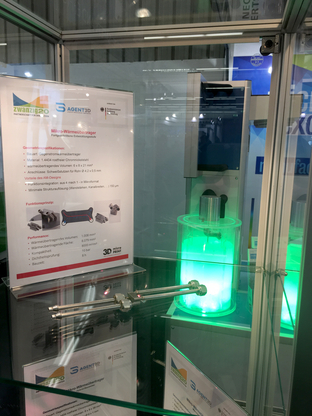

Of course, the Institute of Air Handling and Refrigeration (ILK) could not be missing there. It presented not less than three innovations to the visitors in exhibition hall 5. The significantly refined model of a vacuum liquid ice storage with a transparent reservoir and a shiftable air refrigeration stands for only one application option of the new technology developed by the Institute of Air Handling and Refrigeration (ILK). The interested expert audience was presented how to load and unload the innovative storage technology.

The use of Power-to-Cold (PtC) in an industrial environment is tested and demonstrated within WindNODE, the joint project of the Federal Ministry for Economic Affairs and Energy. Therefor, the Institute of Air Handling and Refrigeration (ILK) is further developing an efficient and especially flexible cold storage technology with pumpable ice. The aim of the development is the generation of liquid ice with a melting temperature of -5 °C. Thus the application of the economic storage material in refrigeration plants such as cold storage houses, dairy factories and breweries shall be rendered possible and energy storage potentials shall be extended.

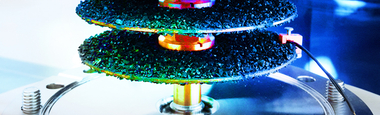

From the technological development proposal (FunGeoS) „Functional Geometrical Structures – Construction Principles for the additive-generative Construction“, the Institute of Air Handling and Refrigeration (ILK) presented the first functional structures on the basis of micro heat transmitters. These small demonstrators partly made a great stir, since many industries set big hopes on the additive-generative production on the one hand and its versatile applications accompanied by functional advantages on the other hand.

The goal of the optimisation are large heat transfer surfaces per volume, respectively a big compactness. The producibility itself via additive-generative procedures is however a marginal condition in the concept development. The concepts‘ efficiency is experimentally identified and compared with each other‘s. Thus, the most suitable concept is identified on this basis. The concepts represent internal structures for possible heat transmitters which are then processed to a complete heat transmitter by means of form feature constructions.

Leading research institutions, the industry as well as small and medium-sized businesses form a strategic alliance for research, innovation and growth with more than 120 partners in the consortium AGENT-3D. Their common goal is to secure Germany’s technological leadership in the central areas of the additive-generative production.

In the framework of „Twenty20 – Partnership for Innovations“, the Federal Ministry of Education and Research supports the project with up to 45 million Euros.

Absorption refrigeration systems, specifically lithium bromide systems must be tested regularly for corrosion. In order to spare the system operators complex and expensive analyses dispatching samples, the Institute of Air Handling and Refrigeration (ILK) team around Dr. Goldberg has developed a quick test, which can be transported in a handy suitcase and which gives information about the system’s state of corrosion. Besides the physical data of the working fluids, the metal content can be measured semi-quantitatively, but also the concentration of the commercially available corrosion inhibitors can be measured by simple quick tests. The analysis suitcase contains recommendations for procedures in case of transgression of threshold values.