You are here: Home / Technology transfer

Micro heat exchangers in refrigeration

3D-printing of micro heat exchangers

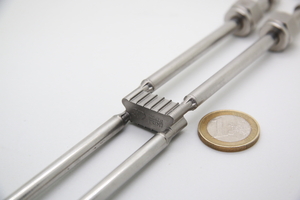

The reduction in the size of structures and components also leads to improved performance in heat exchangers. Micro heat exchangers offer more surface area per volume and achieve higher heat transfer coefficients. The small channels in these heat exchangers ensure that the two fluid streams pass as close together as possible. The key to such heat exchangers is the appropriate manufacturing process.

Preliminary work

In a preliminary research project of the BMWi EURONORM InnoKom-Ost the constructive and technological limits for the production of micro heat exchangers were tested. The following findings were obtained

- Micro heat exchangers allow greater compactness than the state of the art.

- Test heat exchangers achieve a surface-to-volume ratio of up to 7300m²/m³.

- Heat transfer coefficients of up to 12000 W/m²K can be observed.

- Compared to the brazed plate heat exchangers, a reduction of the construction volume by a factor of 25 is thus possible.

- Channel dimensions of approx. 50 to 200 µm can be realized.

For the production of the complicated internal geometry of the micro heat exchanger additive manufacturing processes are particularly suitable. Especially the 3D laser melting processes (Selective Laser Melting - SLM) are interesting. This process has made great progress in the last 10 years regarding the available machines and materials.

In the following joint project FunGeoS-Fluid within the "Zwanzig20"-consortium "AGENT-3D" special solutions for the production of micro heat exchangers were developed. In cooperation with LIM e.V. Mittweida, patent EP2647942 was developed, filed and granted. Together with the partners LHM, 3Dmicroprint and CIM the following findings were collected in this project:

- The 3D printing of micro heat exchangers made of stainless steel is possible.

- Piping can be soldered (preferred) or welded tightly and reliably to micro heat exchangers.

- Reproducible tightness of internal structures must be improved.

Current work

The next step is the investigation of micro heat exchangers as condensers in refrigeration plants within the scope of a BMWi EURONORM InnoKom-Ost project. Within the scope of a BMWi ZIM project, the demanding task of a micro heat exchanger as an evaporator is also being investigated. In the two previous projects the basic feasibility of heat exchangers and their manufacturing processes were the main focus. In these projects the focus is on the specific design adaptation for condensation and evaporation processes and their investigation.

Test rigs

While the production of micro heat exchangers is carried out by partner institutes and companies, the ILK takes over the testing and measurement of the test samples. For this purpose the ILK has an extra test rig for water/water tests on micro heat exchangers. With this test rig the pressure losses and the heat transfer can be measured.

For the measurement of the micro heat exchangers with refrigerant an adapted setup at the "big" heat exchanger test rig is available. This test rig is operated with R134a and can measure small condensers and small evaporators.

Further Projects - Technology transfer

Electrochemical decontamination of electrically conducting surfaces „EDeKo II“

Improvement of sanitary prevention by electrochemical decontamination

Optimizing HVAC operation with machine learning

Intelligent control of HVAC systems – high comfort with low energy demand

![[Translate to EN:] Mikrowärmeübertrager](/fileadmin/_processed_/c/0/csm_ILK_komplett_52ae3f1a22.jpg)