You are here: / Home

Mass Spectrometer

Determining the composition of gas mixtures in the high or ultra-high vacuum range

Mass spectrometry is a method for determining the composition of gas mixtures in the high or ultra-high vacuum range. It can be used to carry out qualitative and quantitative gas analyses and leak detection or to determine trace contamination.

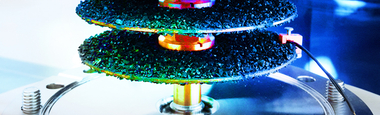

The individual neutral gas particles are ionized by an electron impact ion source and separated from each other in an electric quadrupole field according to their mass-to-charge ratio. The filtered ions are then recorded by a detector. The ion current detected is proportional to the partial pressure of the respective gas component. For a more precise quantitative gas analysis, the relatively operating measuring instrument can be calibrated with a calibration gas.

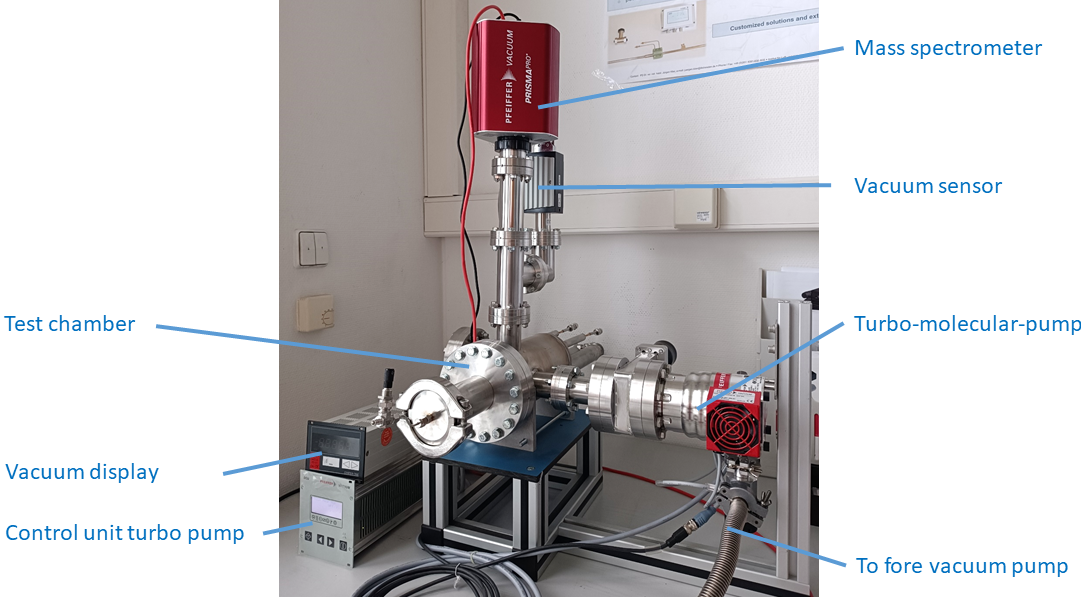

The test set-up consists of a test chamber with a connected turbo-molecular-pump and fore vacuum pump. The mass spectrometer requires a vacuum <1,5×10-7 psi (<1×10-5 mbar) to be able to measure with high precision. The mass spectrometer and a vacuum sensor are mounted on the test chamber. The mass spectrometer is connected to a measuring PC with corresponding software.

Available measurement modes are:

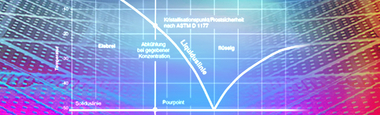

- Vacuum analysis, to determine residual gas components, evaluation as a plot of ion current and mass

- Leak detection, with helium or another tracer gas, the ion current of the tracer gas or the corresponding mass is recorded and plotted over the time

- Mass spectrum, evaluation of ion current and mass with user-defined specifications and time trend

| Paramter | Test value |

|---|---|

| Analysis | Vacuum analysis, leak detection, mass spectrum, trace contamination |

| Detectable gases | H2, He, N2, H2O, O2, CO2 usw. |

| Mass range | 1 – 100 Da (1,66×10-27 – 1,66×10-25 kg) |

| Detection limit | 1.5×10-15 psi / 3×10-13 mbar |

| Min. vacuum pressure and max. temperature range | <7.3×10-6 psi / 5×10-4 mbar, < 150°C / 302°F |

[Translate to EN:]

Your Request

Further Projects

Tribological investigations of oil-refrigerant-material-systems

Modified Almen-Wieland wear testing machine

Influenced melting point of water by magnetic field

Controlled sub-cooling of products in freezing processes