You are here: / Home

Tribological investigations of oil-refrigerant-material-systems

Modified Almen-Wieland wear testing machine

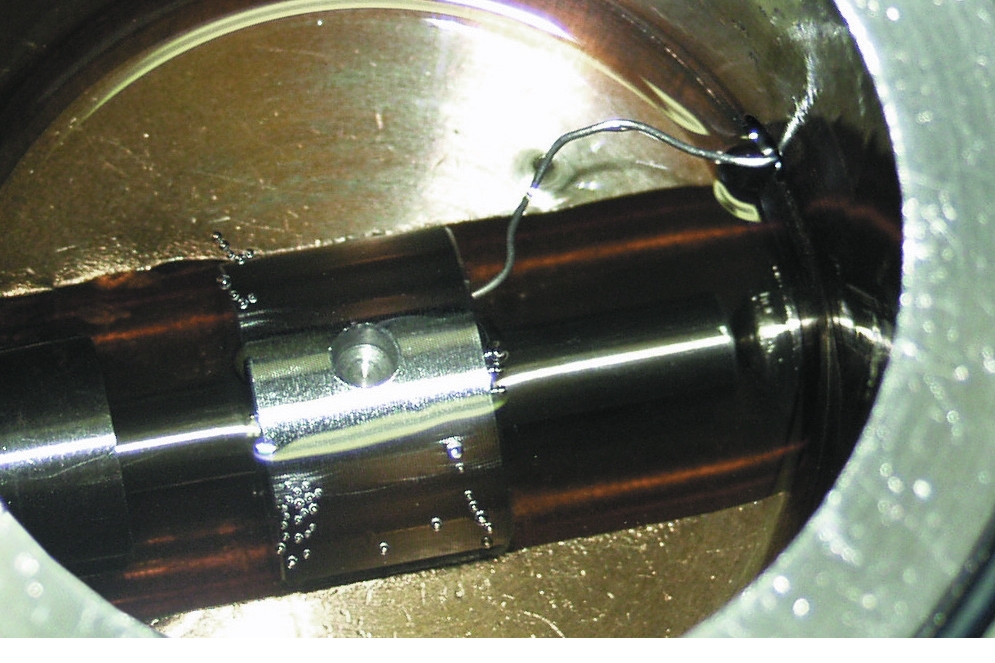

The modified Almen-Wieland wear testing machine is used for the determination of the tribological properties of oil-refrigerant-bearing-systems under mixed friction conditions. The interaction of lubricants, additives, refrigerants and materials is tested. On the basis of these investigations refrigeration oils and materials could be preselected, but the tests can not substitute field test with refrigeration machines.

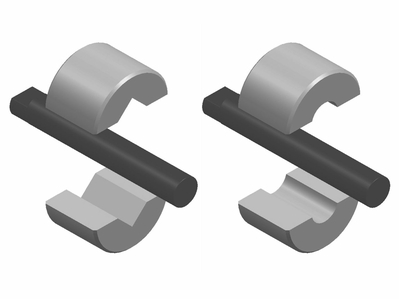

Principle

Two half bearings are pressed hydraulically against a test pin rotating horizontally in the lubricant.

The extreme pressure failure, i. e. the load bearing capacity of oil, is determined by increasing continuously or stepwise the test load until seizure of pin and bearing occurs and the pin breaks. The coefficient of friction and the wear are determined with constant (low) load applied during a prescribed test time.

Specialties

- Hermetic test cell, which allows testing with refrigerant pressures up to 10 bar.

- Thermostated test cell for a defined lubricant temperature.

- Continuous record of fest force, turning moment, pressure of refrigerant, temperature and wear.

- Use of both Almen-Wieland and half bearings with Falex geometry (dimensions of the V-block than the original Falex bearings according to ASTM D 3233).

- Adaption of the tribological system by choosing materials of test pins and half bearings.

Our services

- Evaluation of lubricant-refrigerant-material-systems by load bearing capacity of lubricant (extreme pressure failure load), coefficient of friction, wear, changes of lubricant

- Evaluation of tribological systems after changing lubricants, refrigerants or bearing materials in order to minimize expensive field tests

- Failure analysis

Your Request

Further Projects

Reduction of primary noise sources of fans

...using numerical and experimental methods with contra-rotating axial fan

Software for technical building equipment

Design cooling load and energetic annual simulation (VDI 2078, VDI 6007, VDI 6020)