You are here: Home / Measurements and Tests

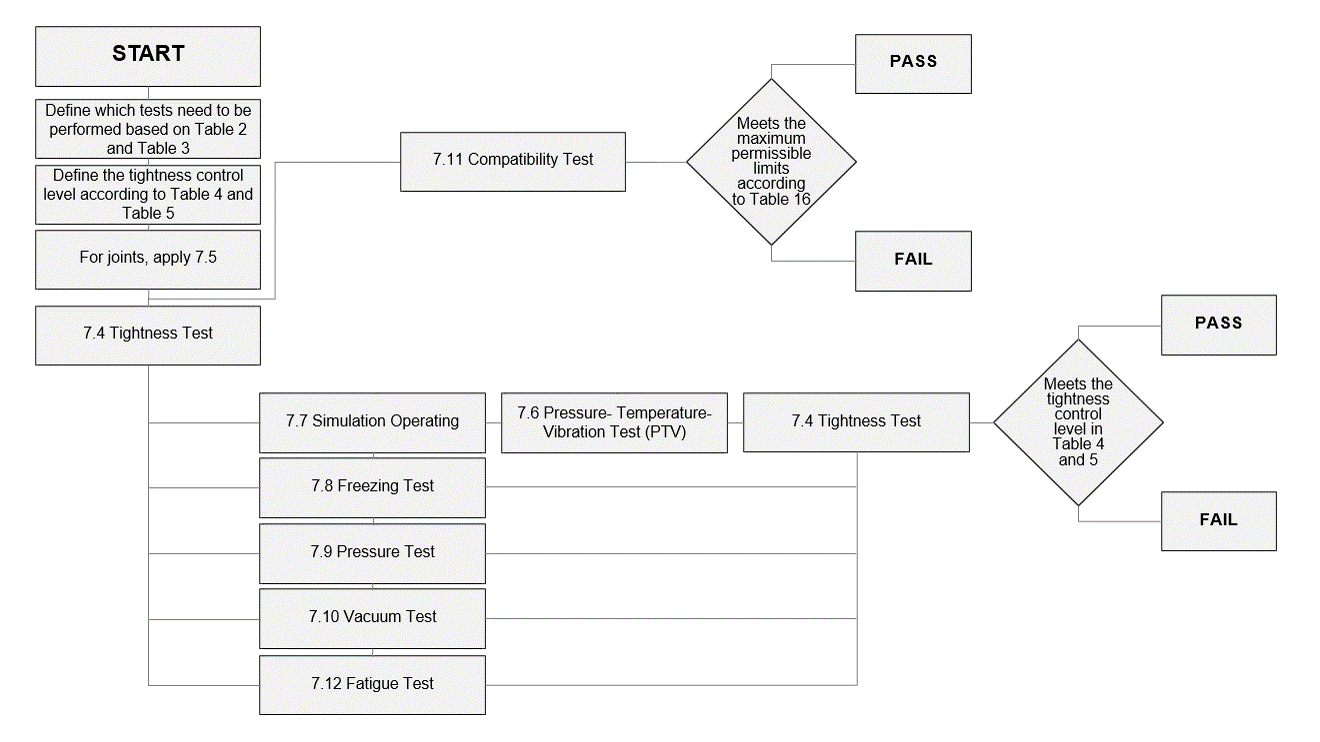

Investigation according to DIN EN ISO 14903

These tests according to DIN EN ISO 14903 are possible at ILK Dresden

§7.4 Tightness Test

§7.6 Pressure- Temperature- Vibration Test

§7.7 Simulation Operating

§7.8 Freezing Test

§7.9 Pressure Test

§7.10 Vacuum Test

§7.11 Compatibility Test

§7.12 Fatigue Test

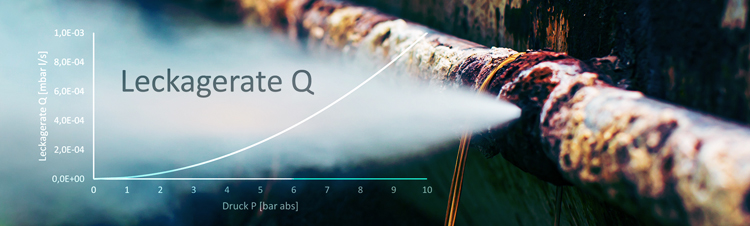

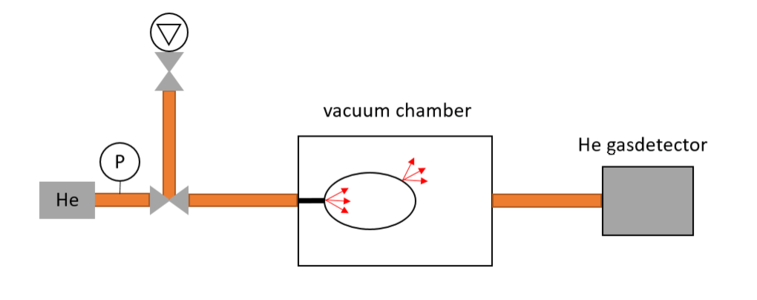

§7.4 Tightness Test

- Tightness control according to classification in DIN EN ISO 14903 at room temperature

- In each case per connection or component (test sample) before and after the respective modules

-

Permissible leakage rate (helium) depending on the selected tightness control level E.g. A1 with Q ≤ 7,5E-7 Pa m³/s = 7,5E-6 mbar l/s @ 10 bar rel., 20 °C

-

Testing with helium gas detector in vacuum method or substitute method

-

Procedure section 10 according to DIN EN 13185, Detection limit 5,0E-13 Pa m³/s helium

-

Test gas helium

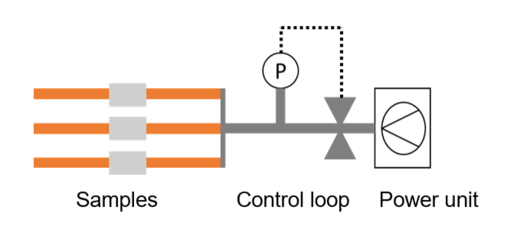

§7.6 PTV Test and if necessary §7.7 Simulation Operating

- Tmin: -40 °C (specified by the customer)

- Tmax: +140 °C (specified by the customer)

- Test pressure PSmax: 100 bar rel. (specified by the customer)

- 50 Temperature changes

- 200 Pressure pulses

- Subsequent vibration test < 200 Hz, 1 Axis, 2 Mio vibrations, const. amplitude

- Simulation Operating, E.g. 25x open and close the connection

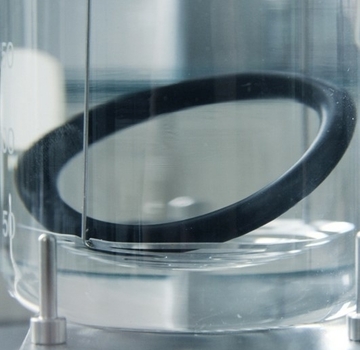

§7.8 Freezing Test

-

Freezing test in a vacuum test chamber. The test specimen is exposed in a vacuum chamber filled with water at 500 mbar abs (+ 0, -100 mbar) for at least 10 min. The pressure is then increased to atmospheric pressure.

-

Afterward, the test specimens are stored at -15 °C (or below) for at least 30 min in a temperature-controlled cabinet and then exposed to water at ambient temperature for at least 5 min., these steps are repeated a total of 30 times

§7.9 Pressure Test

- The pressure test is performed at 5xPS for 1 minute

- Medium oil

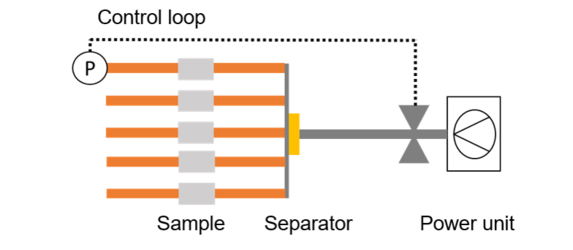

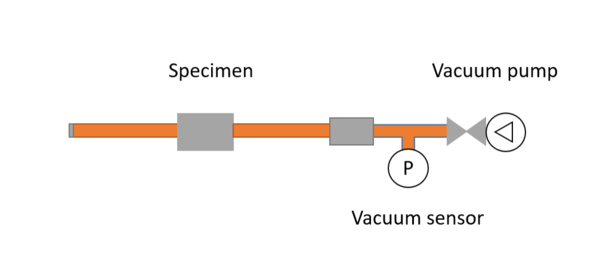

§7.10 Vacuum Test

- The test samples are subjected to the test to confirm that they are able to withstand a vacuum with an absolute pressure of 6.5 kPa for 1 h without leakage.

- For this purpose, the pressure is monitored and it is checked whether the pressure increase Δp after 1 h is less than 0.2 kPa. The effect of the temperature change on the pressure is taken into account.

§7.11 Compatibility Test

-

Investigation into the chemical compatibility of the materials

-

Aging for 336 h at 50 °C in refrigerant-oil atmosphere (for elastomer materials)

-

Aging for 1000 h at 50 °C in refrigerant-oil atmosphere (for thermoplastic materials)

-

Determination of mass, volume and hardness before and after aging

§7.12 Fatigue Test

-

Fatigue test, 250.000 Pressure cycles at max. 50 changes per minute

-

Test range between test pressure PS and atmospheric pressure, test medium: water