At the Innovations Day at the Federal Ministry for Economic Affairs and Energy, the annual performance show of small and medium-sized businesses was introduced by Christian Hirte, Parliamentary Secretary of State of the Minister for Economic Affairs and Energy as well as the federal government’s representative for small and medium-sized businesses and the new federal states.

About 300 enterprises and research institutions present more than 200 technological novelties to more than 2.000 visitors at the Innovations Day for SMEs. Those novelties were put into practice by support of the Ministry for Economic Affairs and Energy (BMWi).

The Institute of Air Handling and Refrigeration presented a prototype from a successful Euronorm MF project which focused on the development of a noise-reduced pair of running wheels for a compact reverse axial fan.

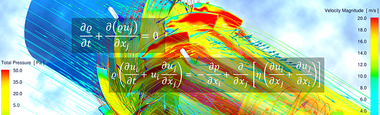

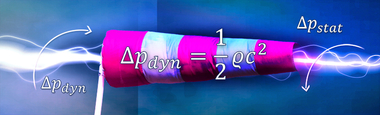

Based on their construction type, reverse axial fans reach a very high power density. However, due to the running wheels rotating past each other with only little space between them, the noise generation also increases. Thus, the fan blades were modified in different ways in the research project and the effects of these modifications were then assessed with the help of an acoustic camera. A special algorithm was developed and tested in order to localise the rotating noise sources. Depending on the frequency, different noise sources could be proven as a result.

By using primary noise reduction, the very high power density of this construction type of turbo machines can be retained even under acoustically challenging operating conditions. Noise reduction is achieved by a special design of the fan blades as well as of the braces which are in the streaming.

![[Translate to EN:] ILK Dresden](/fileadmin/_processed_/1/b/csm_Bild1_42aa0d4c1d.jpg)

![[Translate to EN:] ILK Dresden](/fileadmin/_processed_/8/0/csm_Bild2_e7614b1914.jpg)

![[Translate to EN:] ILK Dresden](/fileadmin/_processed_/0/9/csm_Bild3_6a42071a39.jpg)