A procedure of reprocessing valuable lithium as secondary raw material was developed in cooperation of the ILK Dresden with Johnson Controls Systems & Service and the Freiberg-based company LuxChemtech. Project coordinator LuxChemtech submitted the innovative procedure to the eku Future Prize of the Saxon State Ministry for Energy, Climate Protection, Environment and Agriculture and won the category endowed with the biggest prize. The project coordinator will accept the prize in May 2022 – most likely in person.

Developing and testing resource-conserving procedures and products are not only the guiding ideas of the ILK Dresden, but daily routine for the scientists. The ILK is now making an important contribution to environment and economy with a completely new recycling procedure for used lithium bromide solutions from absorption refrigeration facilities, which has been developed by the ILK and its cooperation partners: the reprocessing of the metal lithium, which is strategically valuable for various future technologies!

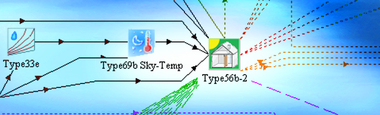

Absorption refrigeration facilities can be found everywhere in the industry where cooling is required and warmth is available at a low cost – for example in server rooms, hospitals, chemical companies or office buildings.

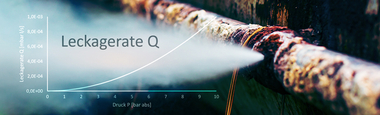

Germany has to import the biggest part of the lithium bromide solution that generates the cooling effect in the absorption refrigeration facilities. During maintenance or the dismantling of the facilities, or when damage happens, the solutions turn into waste as contaminated brine or even as toxic waste. “They were not reusable and thus tons were disposed of.”, knows ILK project leader Dr. Steffen Feja.

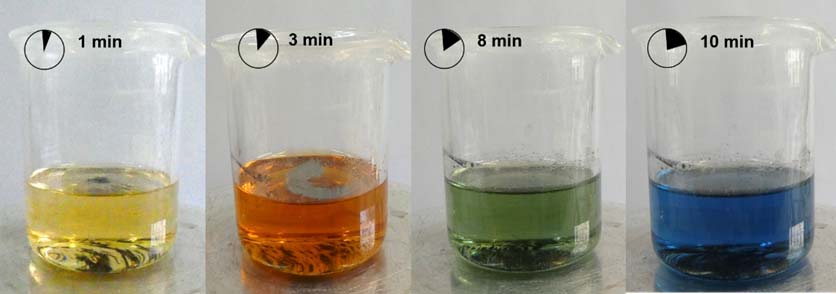

Within about three years, a procedure was developed in cooperation with the company Johnson Controls Systems & Service – first in the chemical labs of the ILK Dresden, and later at the project partner LuxChemtech’s facility – with which lithium bromide solution can almost entirely be made reusable as secondary raw material.

Furthermore, the project partners succeeded in rendering the health-damaging corrosion additives based on carcinogenic chromate compounds, which can be found in the absorption solutions, non-toxic, and dissolve them out completely.

For this new procedure, the project coordinator and Freiberg-based company LuxChemtech received the eku Future Prize worth 20.000 Euros, an award of the Saxon Ministry for Energy, Climate Protection, Environment and Agriculture.