You are here: / Home

Laseroptical measurement

PIV and LDA / PDA

Scope of Application

There are, whether wanted or not, fluid flows at many products. Depending on ambient conditions, boundaries and many other factors such fluid flows will appear in many different ways. Hence it is often very difficult to make predications on the flow itself or the interactions with other components.

Using laser optical measuring methods will show you new potential for optimization:

- Power

- Efficiency

- Pressure drop

- Heat exchange

- Costs

- Design

- Streaming direction

- Noise

This modern method laseroptical measuring has many advantages:

- calibration-free

- non touching

- not invasive

- demonstrative

- fast

At this time fluid flows can be analyzed with two different methods:

- Particle Image Velocimetry

- Laser / Phase Doppler Anemometry

Particle Image Velocimetry

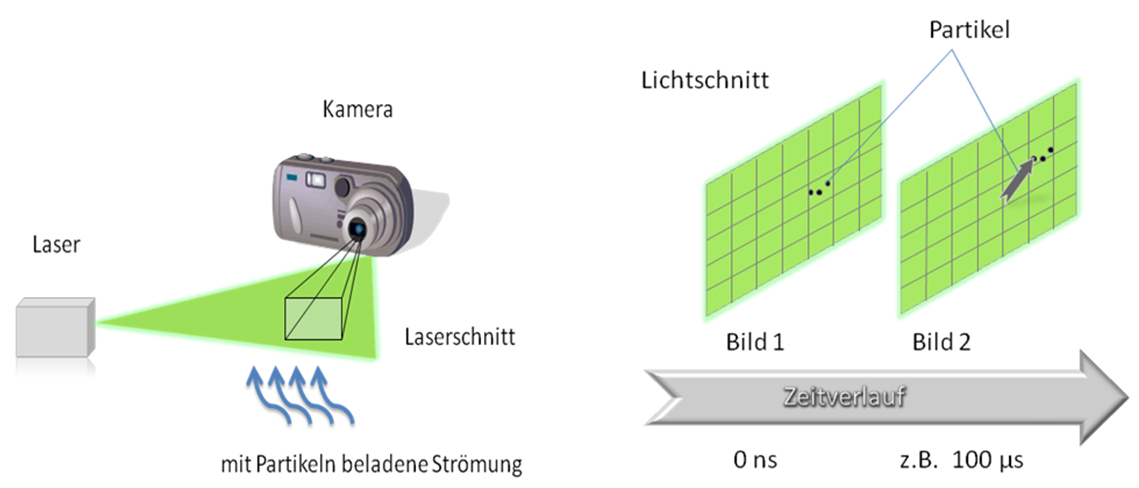

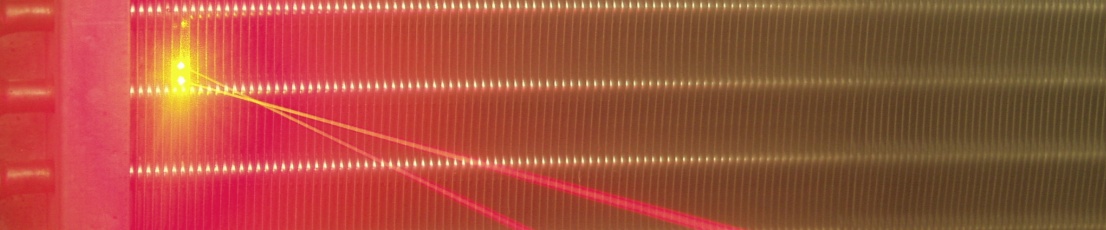

Procedure for the velocity measurement by PIV (particle image velocimetry)

Velocity and direction of a fluid flow is detected by carried particles in the fluid itself. The fluid flow is therefore exposed to light in a plane for a short time. Comparing two pictures shows the displacement of single particles. With this information the velocity field can be calculated.

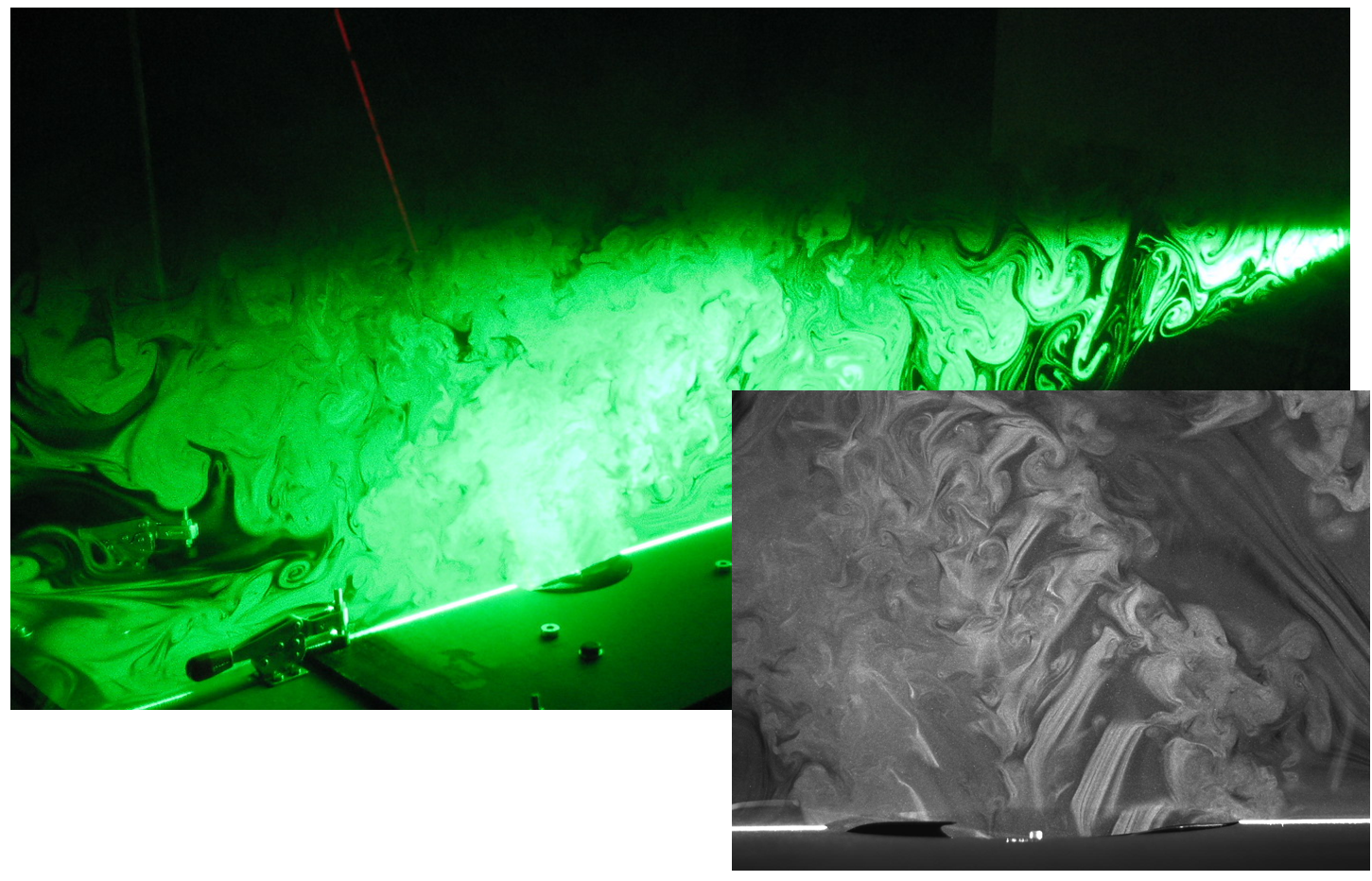

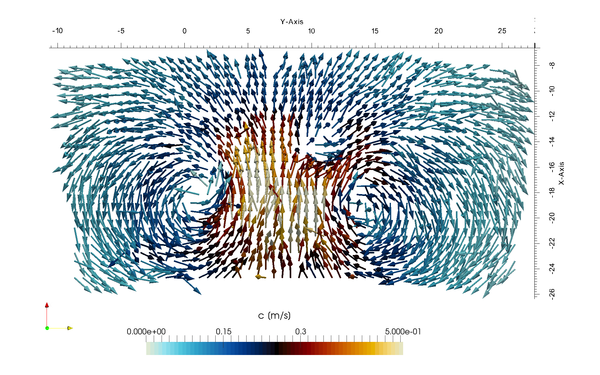

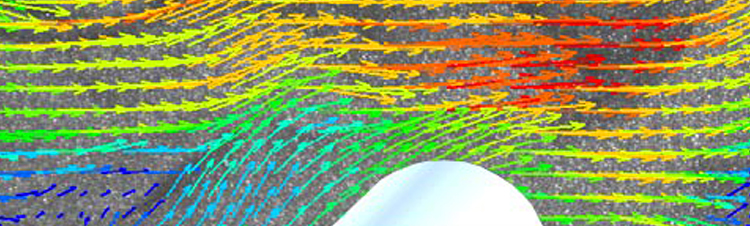

1. Video – flow with Seeding particles. The following video shows the exposure of a cuvette with fluorescent microparticles. The particles are illuminated in a laser cut and each two pictures are recorded within a short time distance. 2. From these exposured double-pictures the velocities at the exposure layer can be calculated. The time dependent velocity course is shown in this video. 3. Like shown in the last video the flow course is presented clearly by mean value formation. The amount of velocity is marked in terms of colour.

possible task:

- Detection of the streaming structure at air outlets, exhaust equipments, fans and similar components

- Optimization of flown through components as ducts, heat exchanger and housings

- Getting boundary conditions for CFD simulations

- Detection of vortices

- measurement of transient streaming

- Getting the mean values of transient streaming

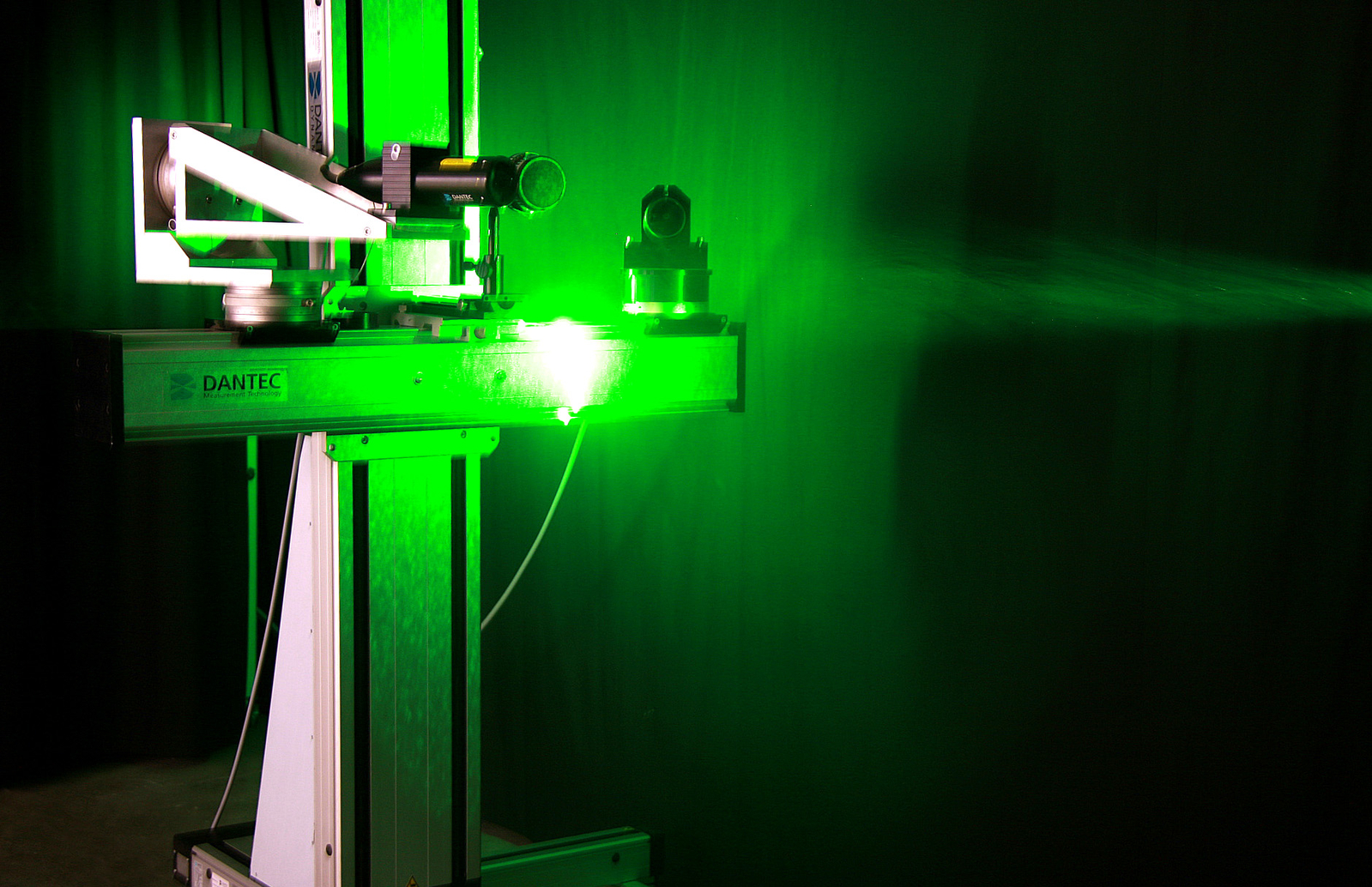

System 1 made by Dantec

- Double-puls-laser 532 nm 5ns / 50 mJ two cavities maximum 21 Hz

- FlowSense Camera 2M with 1600x1200 pixel maximum 15 Hz

- HiSense 610 with 1600x1200 pixel maximum 15 hz

System 2 made by Dantec

- Double-puls-laser 532 nm 5ns / 200 mJ two cavities maximum 15 Hz

- FlowSense Camera EO 4M with 2048x2048 pixel maximum 8 Hz

- guiding arm for easy positioning of the light sheet

Planar PIV (2d2c)

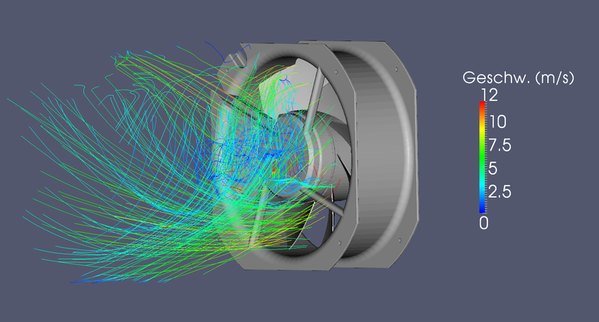

Using a planar PIV the velocity field within a plane can be measured. Advantagously there is a fast system and a flow visualisation giving first impressions of the flow one may interested in. Furthermore this setup, having one camera in his simplest configuration, can be upgraded by further cameras. This leads to fields of view about 1,8mx0,5m or 1mx1m, wich can be measured at once. Application examples are meaurements insisde and outside of cars as well as measurements at large fans

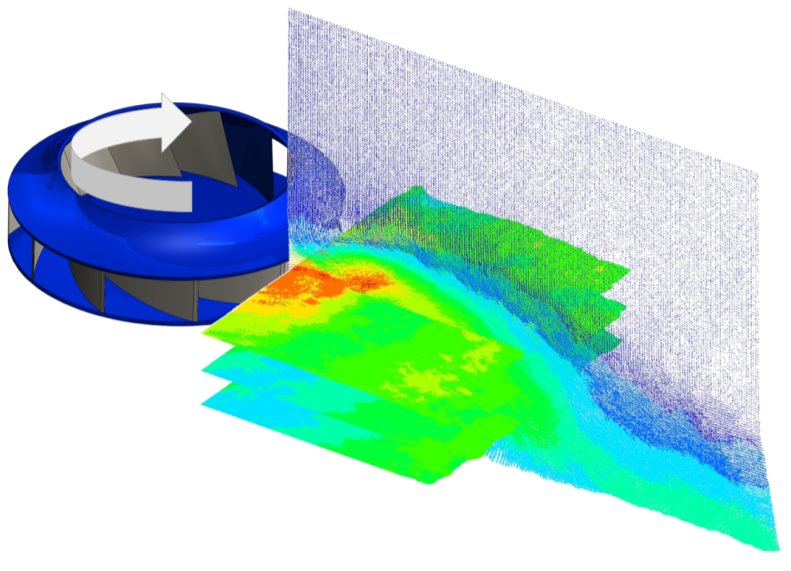

Stereoscopic PIV (2d3c)

Applying a second camera in addition to the setup of a planar PIV a thrid velocity component perpendicular to the illuminated plane can be measured. The picture presents the outlet velocity at an axial fan as an example. The measured values have been processed using Paraview.

Volumetric PIV (3d3c)

By ilumminating a volume instead of one sheet the fluid motion within this volume in every direction can be measured.

For the calculation of the velocity vectors at first the particles found in the illuminated volume have to be reconstructed. In a second step the displacement of these particles between two different time steps are calculated.

Laser Doppler Anemometry

Publications

Ullrich, S.; Buder, R.; Boughanmi, N.; Friebe, Ch.; Wagner, C.

Numerical Study of the Airflow Distribution in a Passenger Car Cabin Validated with PIV

New Results in Numerical and Experimental Fluid Mechanics XII, Springer International Publishing, 2020, isbn: 978-3-030-25253-3, doi: 10.1007/978-3-030-25253-3_44

Krause, R.; Friebe, Ch.; Kerscher, M. & Puhle Ch.

Investigations on noise sources on a contra-rotating axial fan with different modifications

Clima 2019 REVHA 13th HVAC World Congress, Bucharest, Romania, 2019

Friebe, C.; Velde, O.; Krause, R. & Hackeschmidt, K.

Sound Source Localisation at an axial contra-rotating fan by means of PIV and rotational beamforming

Proceedings of 13th European Conference on Turbomachinery Fluid dynamics & Thermodynamics, ETC13, April 8-12, 2019; Lausanne, Switzerland

Friebe, C.; Velde, O.; Krause, R. & Hackeschmidt, K.

DESIGN AND INVESTIGATION OF A MULTISTAGE AXIAL CONTRA-ROTATING FAN

FAN 2018; International Conference on Fan Noise, Aerodynamcis, Applications and Systems, 18. – 20. 04. 2018, Darmstadt, Germany, 2018, 1-12

Heinrich, M.; Friebe, C. & Schwarze, R.

Experimental and numerical investigation of a gearless one-motor contra-rotating fan

Journal of Power and Energy, 2016, 1-10

Heinrich, M.; Friebe, C.; Bothe, F. & Schwarze, R.

Experimental and numerical investigation of a gearless one-motor contra-rotating fan

FAN 2015, 15.-17.04.2015, Lyon (France), 2015

Buder, R.; Friebe, C.; Hantsch, A. & Kesslau, D.

Geschwindigkeiten und Temperaturen im vertikalen, beheizten Spalt

23. Fachtagung Lasermethoden und Strömungsmesstechnik, 8.-10. September 2015, Dresden, 2015, 1-9

Friebe, C.; Buschmann, M. & Resagk, C.

Transient velocity-temperature correlation in the near-wall region of lazy plume over horizontal surface

The International Symposium on Applications of Laser Techniques to Fluid Mechanics, Lisbon 2014, 2014

Friebe, C.; Yongle, H. & Heinrich, C.

Geschwindigkeiten und Temperaturen im Formierungsbereich eines Auftriebsstrahls über horizontalen Wärmequellen

21. Fachtagung "Lasermethoden in der Strömungsmechanik", 03.-05.09.2013, 2013

Preibisch, S.; Dietzel, D.; Friebe, C. & Buschmann, M. H.

Experimental and numerical investigation of dimplelike protrusions employed in recent heat exchangers

13. European Turbulence Conference, 12.-15.09.2011, Warzawa, 2011

Friebe, C.; Buschmann, M. & Preibisch, S.

Experimentelle und numerische Untersuchungen von Dimple-ähnlichen Verformungen auf Wärmeübertrageroberflächen"

19. Fachtagung "Lasermethoden in der Strömungsmechanik", 06.-08.09.2011, 2011

Pohl, S.; Buschmann, M. H. & Friebe, C.

Dellen und Noppen in Wärmeübertragern

KI Kälte-Luft-Klimatechnik Juli/August 2010, S.28 ff, 2010

Friebe, C. & Krause, R.

Einfluss der Einbaubedingungen auf die Strömung und die Akustik

6. VDI Fachtagung Ventilatoren,16.-17.11.2010, Braunschweig, 2010

Buschmann, M. & Friebe, C.

Heat Transfer Enhancement employing simple machine elements

Colloqium Fluid Dynamics 2009, Institute of Thermodynamics AS CR, Prag, 2009