You are here: / Home

Electrical components in refrigeration circuits

High voltage tests under real conditions

- Electrical components in refrigeration circuits

- Methods of investigation

- Some already existing methods of investigation are described in the following pragraphs.

- Microscopy

- Oil impregnation

- Controlled damage by partial discharges

- Pin-holes

- Comparison of partial discharge resistances

- Statistical analysis

- Visual inspection

- Alternatives to the break down test

- Combined aging of wire twists

- Isolation resistance of sub-assemblies

- Measurement of partial discharges at short voltage pulses

Electrical components in refrigeration circuits

Electrical components in refrigeration circuits are exposed to rough conditions. Normal electrical stress is superimposed by pressure fluctuations, temperature cycles and chemical influences. Under these conditions they have to operate without a chance of maintenance for decades.

Isolation systems in AC electrical components like the enamel of magnet wires, ground isolation materials or feedthrough polymers undergo increasing stress due increasing operation voltages and short rise times of inverter pulses. Details are given in this GAMBICA paper for example.

ILK Dresden has a long history investigating the impact of refrigerants and oils on elastomers and polymers under various conditions (se e.g. here) as well as on the determination of electrical properties of oils and refrigerants (see e.g. here).

Following the increasing demand of investigations on electrical components ILK developed new test procedures and improved its measurement equipment.

In most cases it is requested to simulate the behavior of specimen over the full lifetime cycle. Accelerated aging is applied to achieve results in a reasonable time. Increased temperatures, concentrations, voltages, shortened pulse raise times, mechanical stress and damages or partial discharges may be applied to accelerate aging processes of the electrical components under investigation.

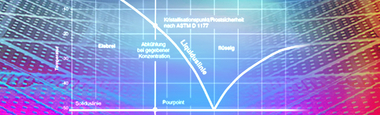

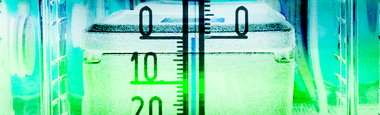

Thermal and chemical aging of electrical components usually takes place in autoclaves. Temperatures up to 200 °C and pressure values up to 100 bar are feasible as well as defined temperature sweeps and pressure fluctuations. The test samples may be exposed to gaseous refrigerant atmospheres, pure liquid refrigerant, oil-refrigerant mixtures or any other substance to which their stability has to be tested.

For simultaneous thermal, chemical and electrical aging either the original compressor casings or special autoclaves are used.

Methods of investigation

The following devices and procedures may be applied to get a maximum of information out of the investigations.

- Microscopic investigation

- 60 channel corona discharge facility with short rise time pulses (peak voltage up to 1500 V, typical rise time 200 - 400 ns)

- Surge generator for stator winding investigations, if required in combination with partial discharge measurements

- Determination of breakdown voltage up to 12 kV a.c.

- Measurement of isolation resistance of electrical components in closed systems with oil and refrigerants

- 18 channel high voltage multiplexer for long term isolation resistance measurements with free choice of measuring time (e.g. 60 s), measuring resolution (e.g. 1s), repetition interval (e.g. once a day), may be combined with an automatic electrical stress - measurement - switch

- Partial discharge detection at repetitive pulses with short rise times or at a.c. high voltage with two detectors:

- narrow band UHF-antenna,

- active narrow bandwidth cable coupling

- HV-pulse generator with variable voltage (peak up to 2500 V) , frequency (up to 50 kHz), pulse duration, wave form, polarity and rise time (down to 50 ns),

- impedance spectroscopy, measurement of dielectric properties.

Some already existing methods of investigation are described in the following pragraphs.

Microscopy

Oil impregnation

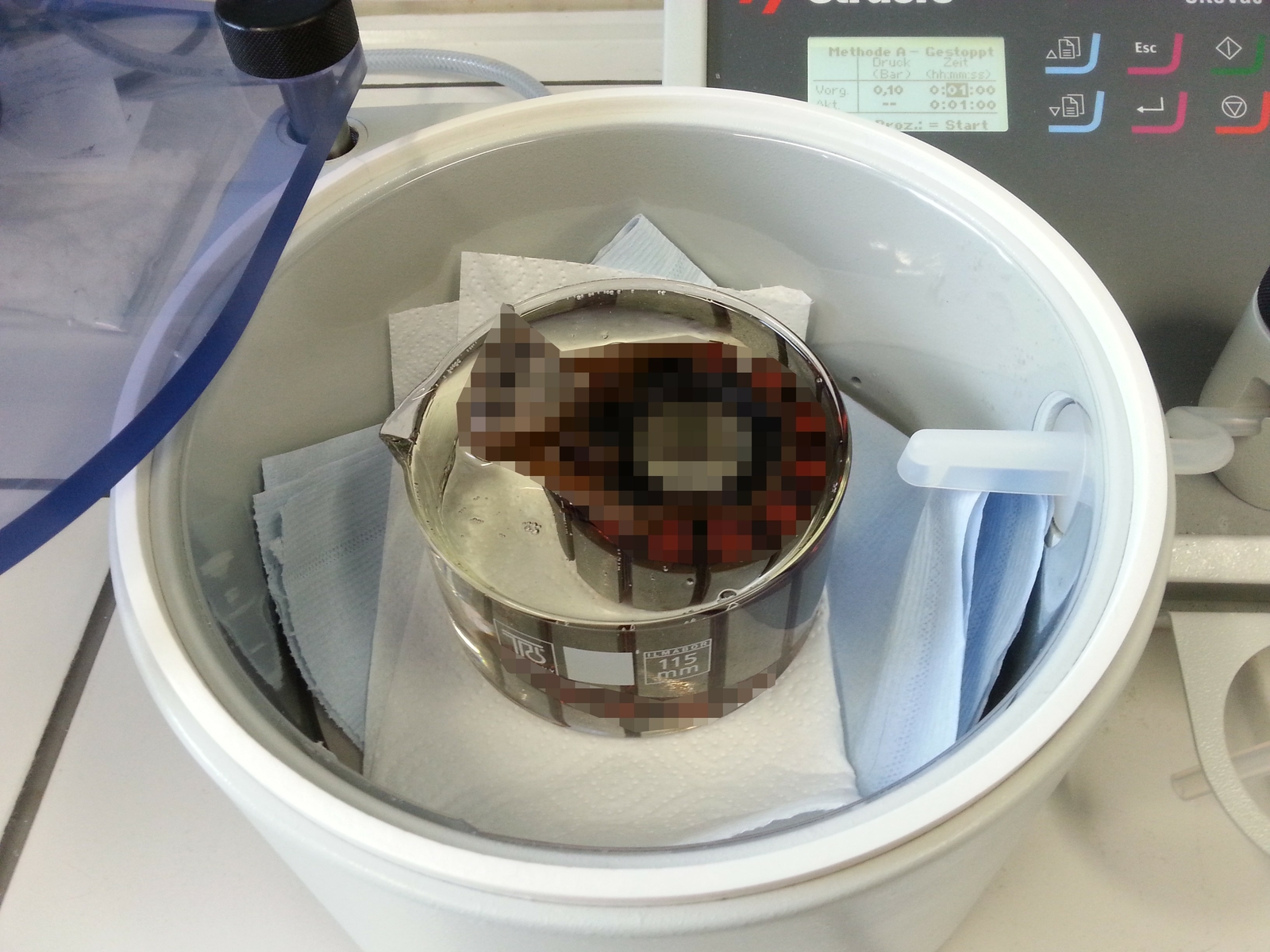

Electrical components as for example stators are tested for partial discharges or with surge pulses before and after aging. In case aging takes place in oil the stators have to be prepared for the initial measurements by vacuum impregnation of refrigeration machine oil. This ensures equal test conditions for the before-and-after-comparison regarding oil wetting.

Controlled damage by partial discharges

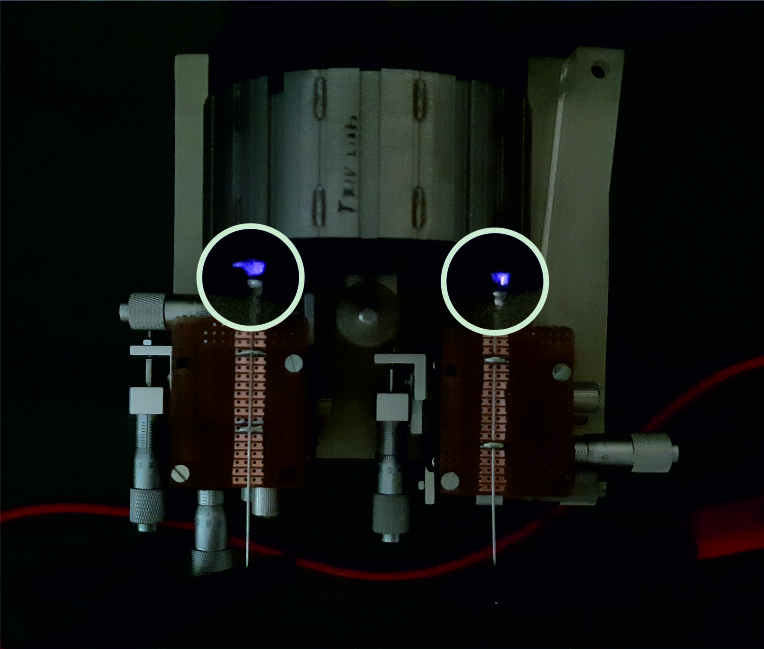

One form of electrical aging is the application of partial discharges (PD). The isolation system is stressed by accelerated particles, ozone and UV irradiation in this case. If these discharges occur over longer periods of time an electrical brake down may be the result. The following picture shows the local application of corona discharges to magnet wires of a stator prior to a thermal chemical aging.

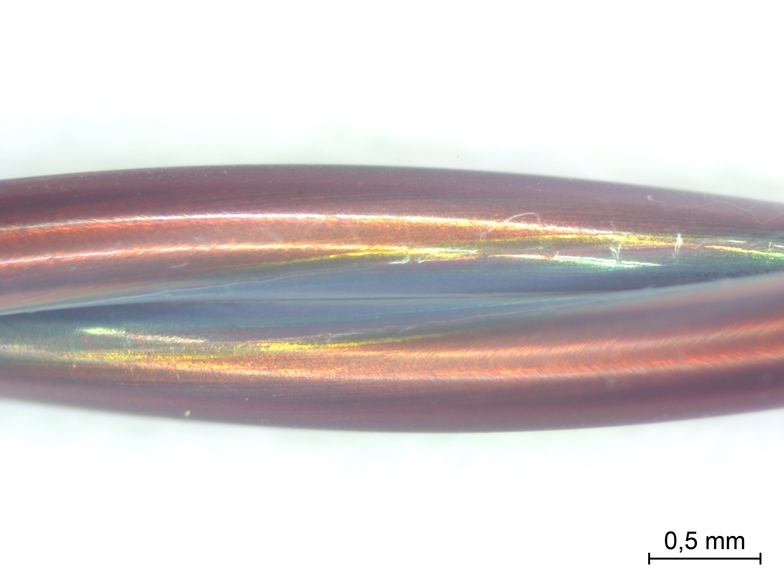

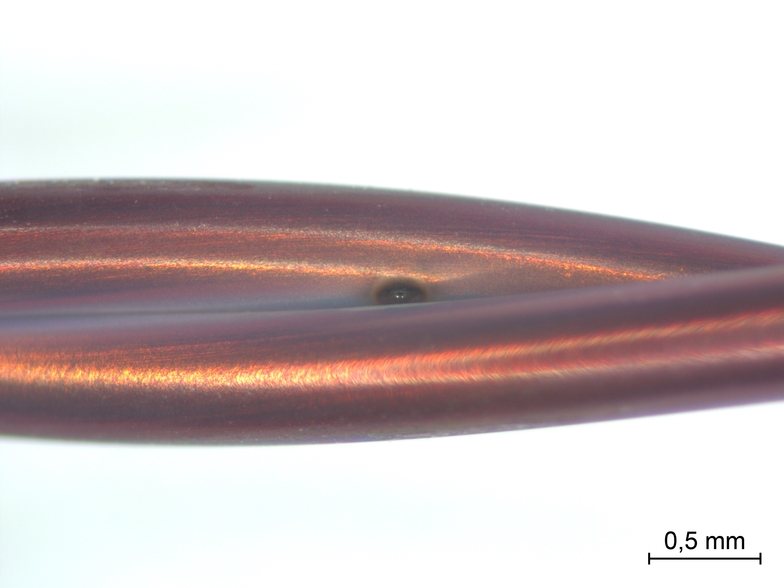

Pin-holes

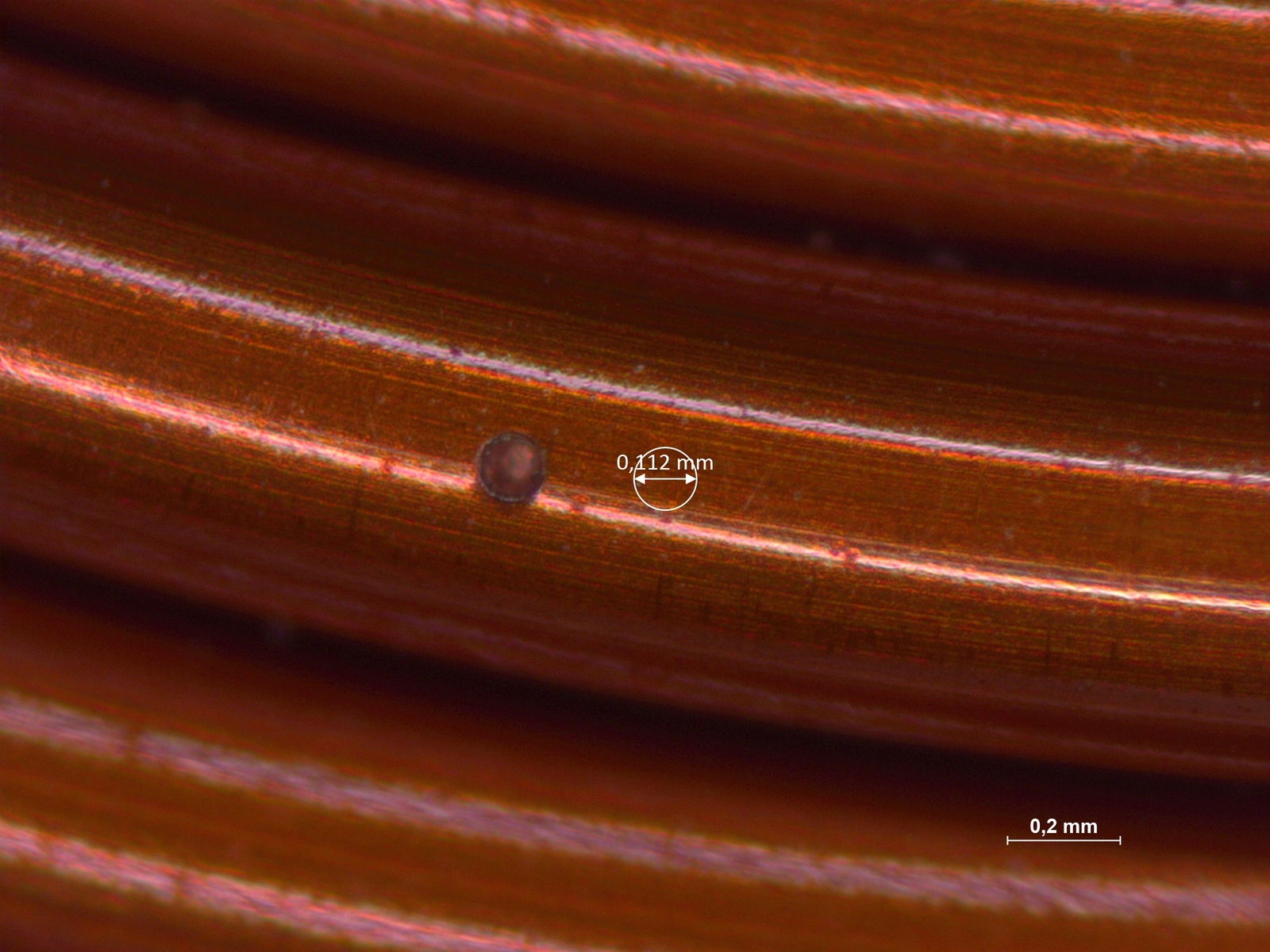

How behave pin-holes in wire isolations under typical refrigeration cycle conditions? Preparing magnet wires and expose them to thermal chemical aging gives first indications. The picture shows an “artificial” pin-hole prepared prior to an aging with pulsed voltage and simultaneous contact to an refrigerant-oil-mixture.

Comparison of partial discharge resistances

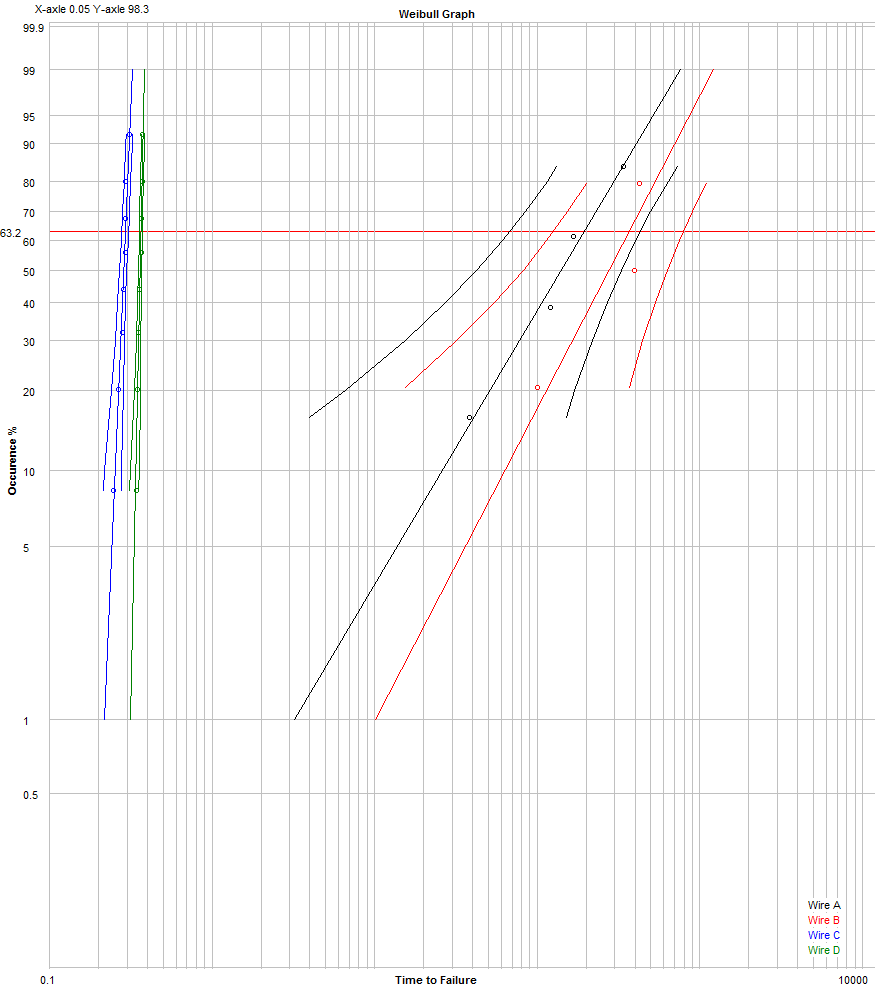

Manufacturers provide a great variety of magnet wires types. Most of these wires are advertised as partial discharge resistant. But which one is “more” resistant than the other? And, is there a change of this property after aging?

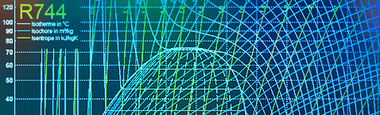

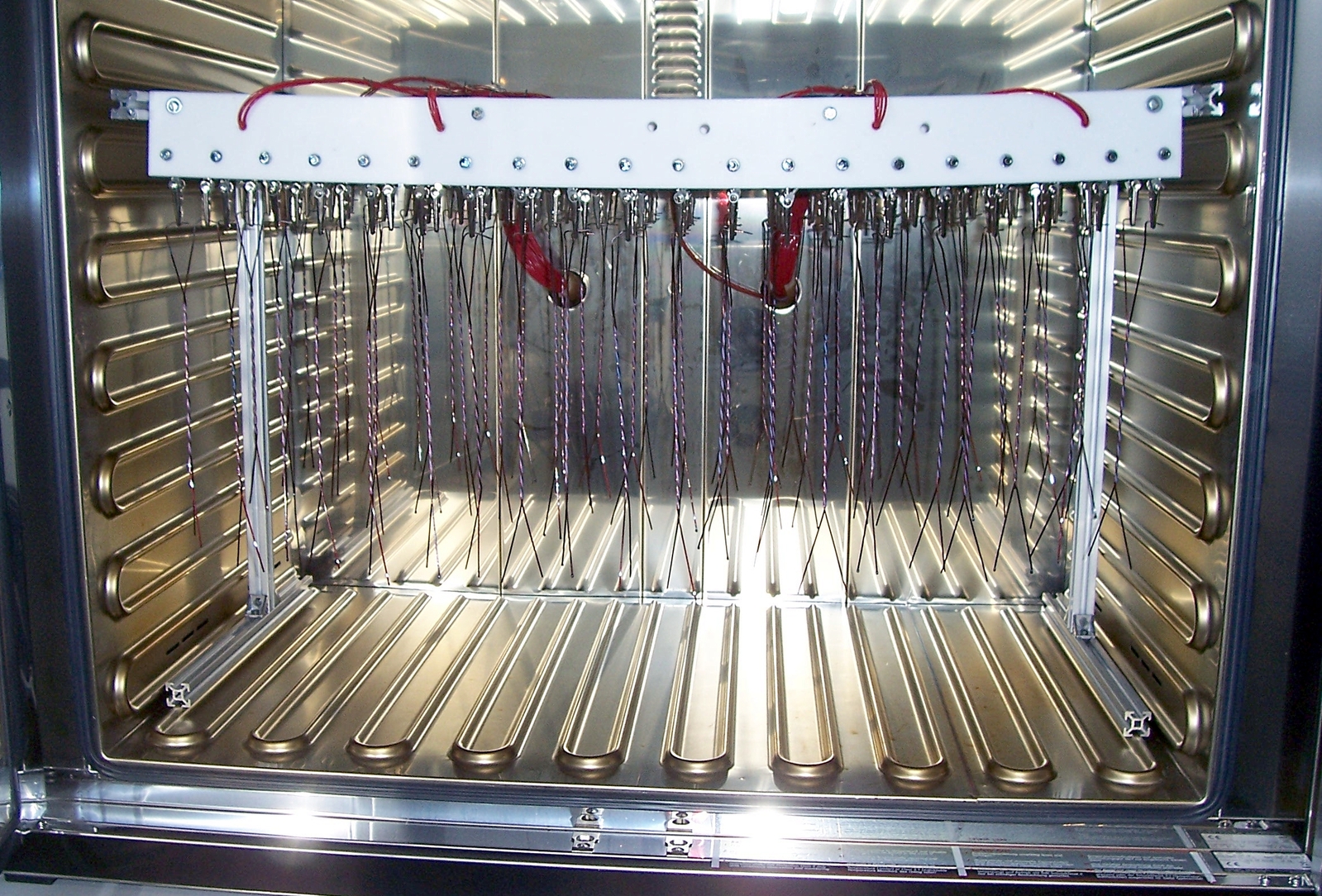

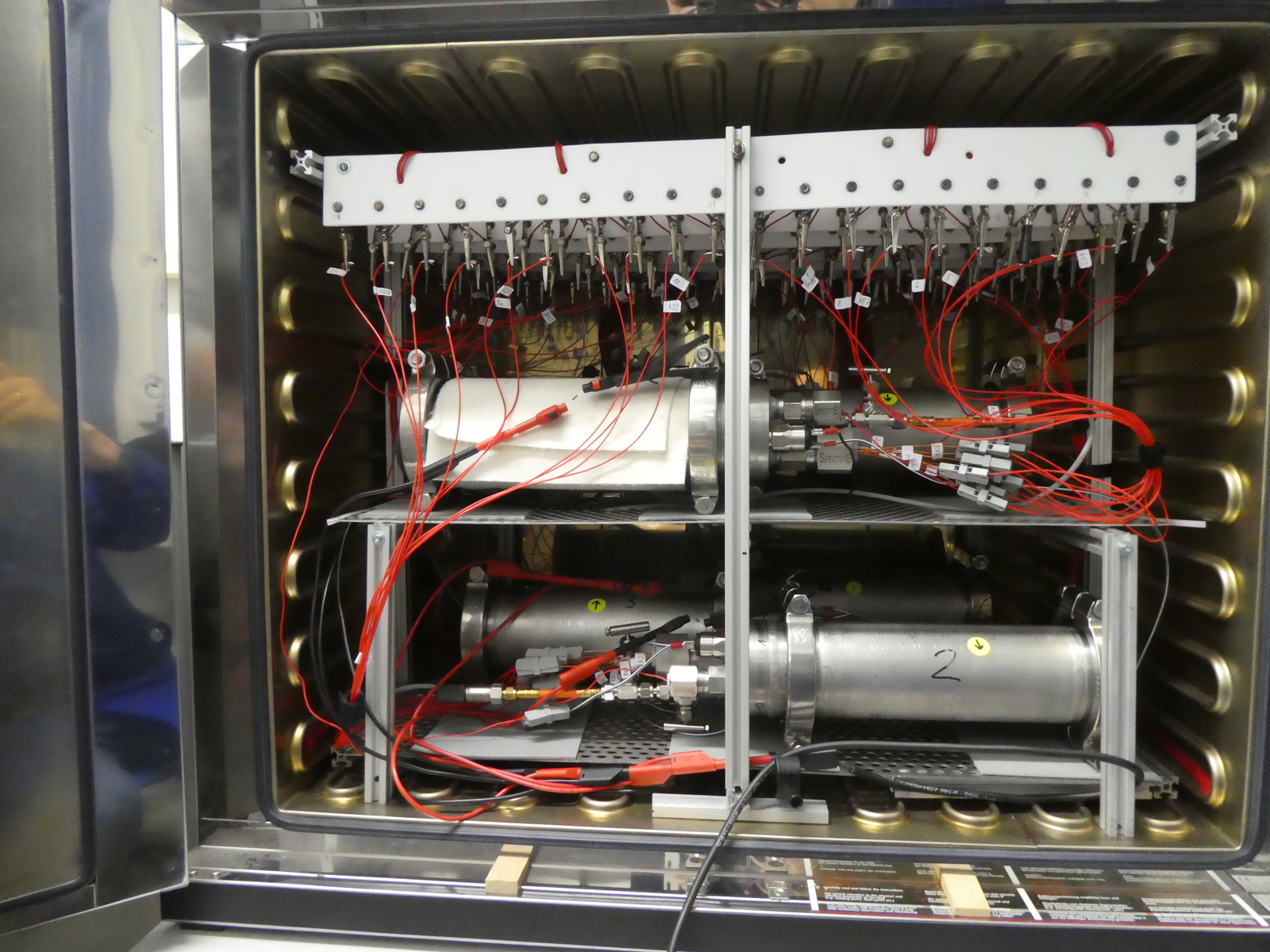

The resistivity against electrical stress including partial discharges of enameled wires can be compared with reasonable statistics by means of a special test set-up in a short time. 60 twisted pairs are simultaneously exposed to 1500 V peak, 16 kHz short rise time pulses at a temperature of up to 180 °C. Every twist is monitored separately for breakdown. Result of this procedure are times to failure of the different wire types which are compared to each other.

Statistical analysis

Visual inspection

Alternatives to the break down test

Another aspect is that usually the breakdown voltage is applied as measure for the impact of an accelerated aging process on the electric strength. But practice showed that the picture of statistical analyses is more clear using times to failure after an electrical stress tests including partial discharges than using break down voltages after a simple high voltage test.

Combined aging of wire twists

The electrical stress tests are usually carried out in an air atmosphere. But what happens when a refrigerant is the circumfluent gas? To answer this question special autoclaves with high voltage feedthroughs were designed and set up to stress twisted pairs under refrigerant atmosphere.

Isolation resistance of sub-assemblies

From its natur an oil refrigerant mixture is a dielectric. It has a high volume resistivity. But what happens inside a compressor when this mixture is enriched with water and further impurities and an applied voltage fosters electrochemical processes? Does this influence the isolation properties of the compressor?

A test set-up was developed to investigate this process at 18 specimen simultaneously. High voltage pulses of the required polarity are applied to them. From time to time this procedure is interrupted and the isolation resistivity is measured for 60 s at one compressor after the other. All this happens automatically and the measuring device fills a database. This test can be combined, for example, with the methods of defined pre-damage mentioned above.

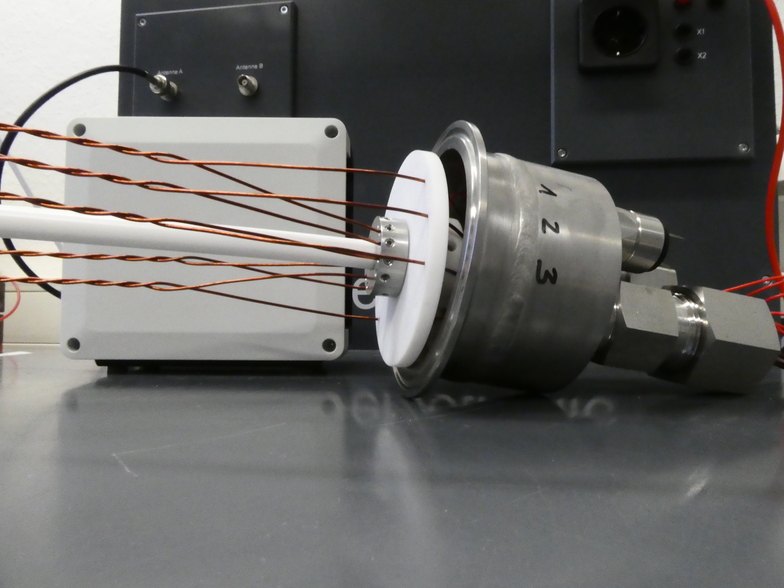

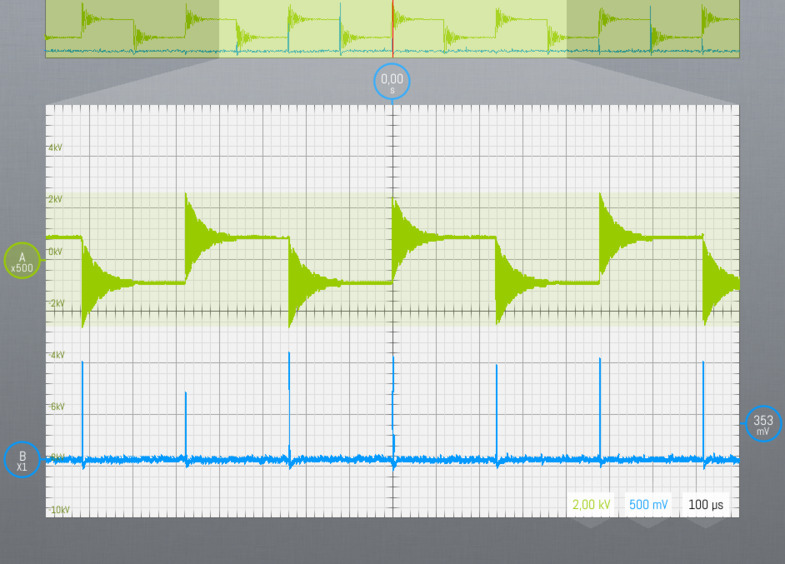

Measurement of partial discharges at short voltage pulses

Operation voltages of MAC compressors rise higher and higher. What about partial discharges (PD) inside these components? Do they occur?

This question is difficult to answer because the housing of the compressor is tight for electromagnetic radiation and modern compressors come with flanged variable frequency drives (VFD) so that the stator connectors are not directly assessable. There are two ways to detect PD in this case: removal of the VFD so that the connectors can be enclosed by a wire sling. This sling is the sensing element of a high sensitive UHF PD detector. An other way to look inside of a compressor would be the installation of a dielectric window into the housing. Leaving radiation which originates from PD impulses can be detected by a UHF narrow bandwidth antenna which is also part of the PD detection system.