You are here: / Home

Investigation of materials

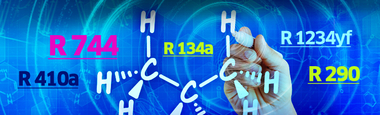

Investigations regarding the compatibility of materials with refrigerants, oils and heat transfer fluids

Our portfolio includes testing

- of materials such as polymers, elastomers, nonwovens, adhesives, and metals,

- of material composites such as wire enamels and hoses, as well as

- of components and assemblies

together with refrigerant and oil (also under pressure) or with heat transfer fluids as well as

- of the autostability of oil and refrigerant together with catalyst metals.

We offer tests according to common standards and company standards, but we are also happy to work with you to develop test scenarios tailored to your requirements

Our range of services:

- Testing of standard samples and components under the influence of refrigerants, refrigerating machine oils and heat transfer fluids in accordance with

- national and international standards, including

- ANSI/ASHRAE 97

- DIN EN ISO 14903

- DIN EN ISO 23936-2

- DIN ISO 1817

- Norsok M-710

- standards of automotive industry, both OEM and suppliers

- standards of compressor manufacturers.

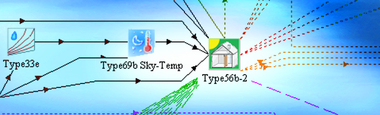

- For aging tests our lab is equipped with:

- Pressure vessels (autoclaves) with volumes from 300 ml to 2000 ml (for pressures up to 200 bar)

- ovens/climate chambers for the temperature range from -40 °C to 300 °C.

- The tests include:

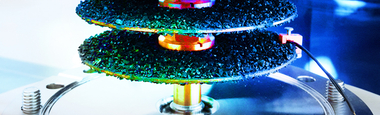

- swelling behavior

- hardness (IRHD, µShore D, Vickers, Brinell)

- tensile, flexural and compression testing

- compression set under temperature and media loading

- rapid gas decompression

- environmental stress cracking tendency of polymers

- testing of adhesive joints (tensile shear test according to DIN EN 1465)

- determination of the glass transition temperature (DSC)

- permeation properties of elastomers

- Characterization of working fluids

- Total acid and base number of oils

- water content of oils and refrigerants

- IR spectroscopy

- gas chromatography (GC-MS/FID) of refrigerants and oils

- ICP-OES for the determination of metal contents in oils and heat transfer fluids

- electrical properties (incl. conductivity of oils and refrigerants)

The mentioned tests are only a part of our portfolio. If the test conditions or parameters you require are not listed, please do not hesitate to contact us.

Your Request

Further Projects

Tensile and compression testing

Determination of yield strength, tensile strength and elongation at break

Breakthrough Sensor for Adsorption Filters (BelA)

Sensor system for detecting an imminent breakthrough in gas filtration