You are here: Home / Measurements and Tests

Investigation of material-dependent parameters

Investigation of the permeation behavior

Permeation is the penetration of solid matter by another substance. The driving force for this is a gradient of the chemical potential of the permeate. In practice, this gradient is replaced by a measurable quantity such as the pressure gradient. The permeability of a material depends on the surface temperature and is usually specified with the unit \( \frac{\mu g}{cm^2\:min} \)

Without external influences, the permeate always moves in the direction of the lower concentration or the lower partial pressure. For theoretical consideration, permeation can be divided into three sections across the solid:

- Sorption, for example, a gas is absorbed at the surface of the solid

- Diffusion, this gas diffuses through the solid through molecular gaps towards the surface with a lower gas concentration

- Desorption, the gas is released again from this surface

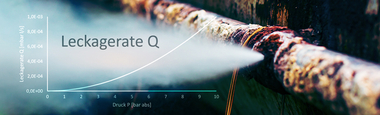

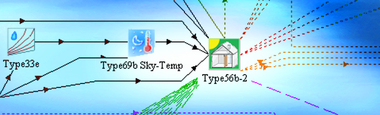

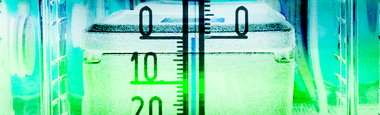

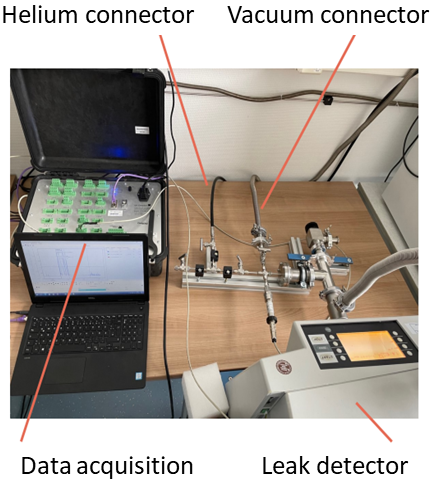

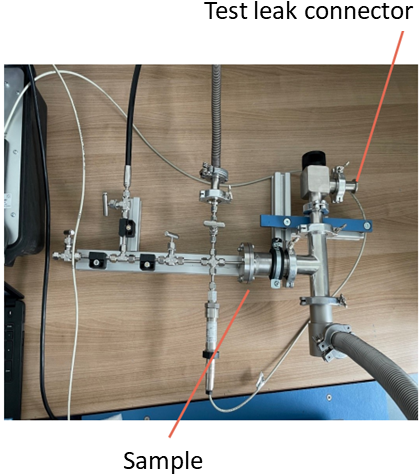

The experimental setup to investigate this process, see the following figures, essentially consists of a sample chamber. The sample is mounted with a seal or against a sealing surface. A test gas with a defined overpressure is applied to the volume on the "left" of the sample. The volume to the "right" of the sample is connected to a detector. The pressure on both sides of the sample, the temperatures and the gas flow rate are measured over a longer period of time (24 - 48 h).

| Parameter | Sample limits |

|---|---|

| materials | plastics, metals |

| dimensions, diameter, and wall thickness | 58 ... 60 mm, 1 ... 3 mm other dimensions on request |

| pressure difference | up to 10 bar (145 psi) |

| temperature range | room temperature, other conditions on request |

| test gas | helium or hydrogen |

| detector measuring range | up to \(10^{-9} \frac{mbar\:l}{s} \), optional with calibration |

Your Request

Further Projects - Measurements and Tests

Tensile and compression testing

Determination of yield strength, tensile strength and elongation at break

Breakthrough Sensor for Adsorption Filters (BelA)

Sensor system for detecting an imminent breakthrough in gas filtration