You are here: / Home

Breakthrough Sensor for Adsorption Filters (BelA)

Federal Ministry for Economic Affairs and Climate Action

05/2023 - 04/2025

Dipl.-Ing. Martin Lauer

+49-351-4081-5377

Sensor system for detecting an imminent breakthrough in gas filtration

The project aims to develop a sensor system that allows the condition of a sorbent for air/gas purification to be reliably monitored and a signal to be given when the sorbent is almost fully loaded. The used sorbent or air filter can thus be replaced as required so that its capacity can be utilized as effectively as possible. At the same time, the protective effect of the filter is ensured throughout its entire lifetime in order to avoid pollutant emissions for people or the environment.

Fields of application

Since 2020, there has been a strong focus on cleaning the air in indoor areas. In addition to particulate pollution, gaseous substances can also quickly have harmful effects on health. In order to remove these components from the air, the use of sorbents (usually activated carbon) is common. Most kitchen extractor hoods and many room air purifiers are equipped with this type of technology. Other areas of application for sorbents can be found in the ventilation of protective rooms/cabins, in the exhaust air purification of industrial processes, in the provision of clean process air and, increasingly, in stationary room air filtration.

The question of the right time to replace the sorbent poses a problem for operators. Even if the sorption unit is equipped with cost-intensive gas monitoring technology (only in large systems), the information for the necessary change of sorbent only comes with or after the sorption layer has broken through. In the case of smaller filters for indoor ventilation or in mobile applications, no information is available during operation about the condition and remaining pollutant capacity of the sorbent.

For gas purification units used for occupational health and safety purposes, the sorption unit must be replaced at an appropriately early stage. For example, although BG Bau instruction 581 stipulates that driver's cabs must have an appropriately equipped ventilation system when used in contaminated areas, the test standards for the sorption filter only include the type of testing of the filter and no recommendations for the duration of use.

Sorbents are also frequently used as a packed bed in industrial exhaust air treatment to reduce critical gaseous components. The operators of such systems also do not have any indication about the condition of their sorbents. This means that they are either replaced far too early, which ultimately leads to increased costs for exhaust air treatment, or too late, which results in an unacceptable environmental impact due to emissions. For these applications, a sensor system is required that informs the operator when the sorbent has been used up and should be replaced.

Project goal

In this project a sensor system for detecting breakthroughs in adsorption filters is being developed. It enables reliable monitoring of the condition of a sorbent for air/gas purification and generates a signal when a threshold value is exceeded and the sorbent is almost exhausted. The used sorbent or air filter can thus be replaced as required so that its capacity can be utilized as well as possible and the protective effect is maintained over the entire usage time.

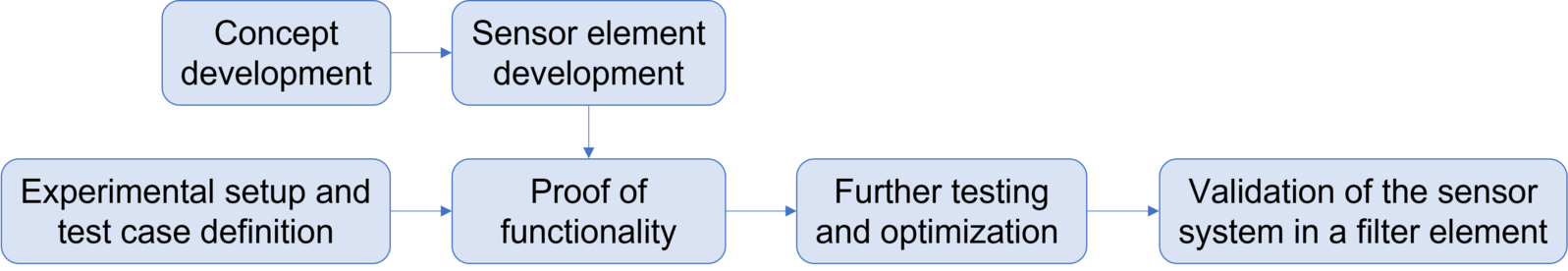

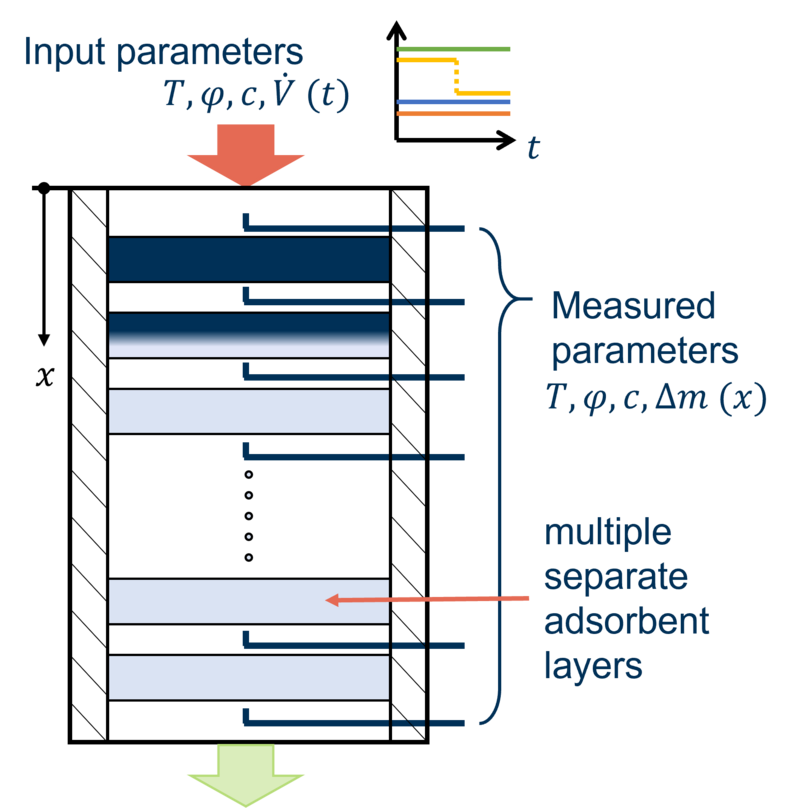

Figure 1: Development steps within the project

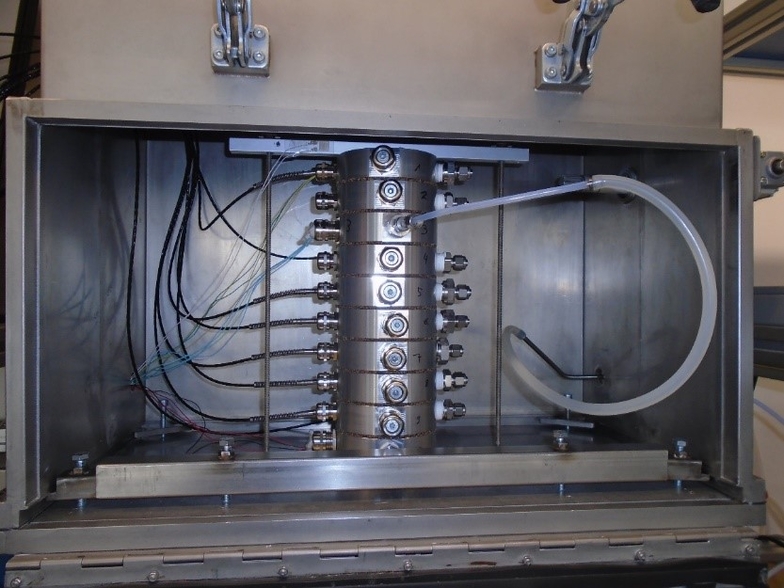

Figure 2: Test apparatus for measurements on activated carbon layers to record the course of the adsorption front under defined conditions

Results / current status

In order to detect the progression of the adsorption front within the sorbent or to localize a momentary pollutant presence, miniaturized sensor elements were developed that can be placed at various positions directly in the filter and are exposed to the air flow. The pollutant-sensitive elements are based on printed electronics so that their production can later be integrated into the manufacturing

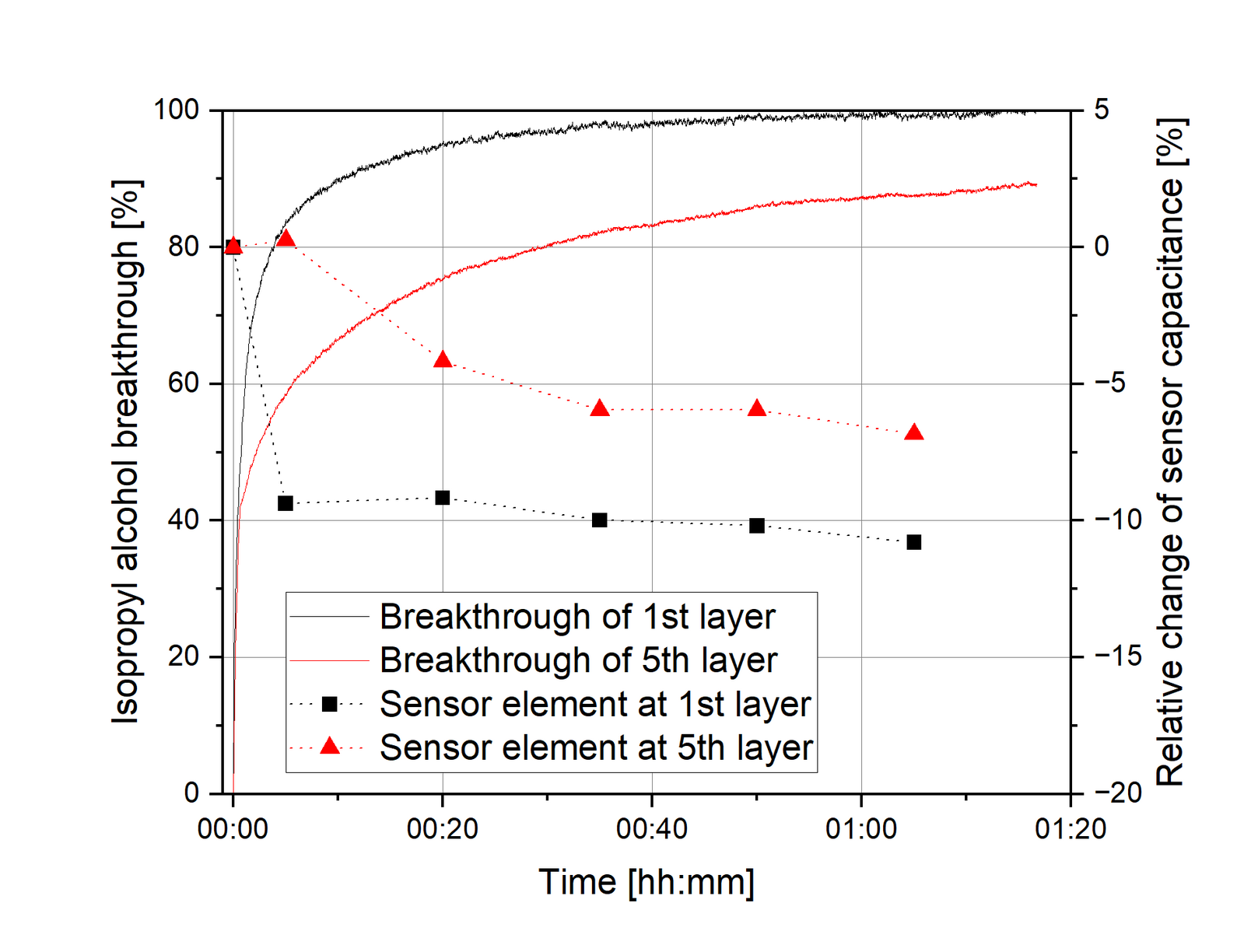

process of the filter at low cost. A separate data acquisition and evaluation unit monitors the status based on the electrical properties of the sensitive elements. A change in the electrical capacitance indicates the presence of a contaminant at the corresponding position of the sensor element and thus a breakthrough or consumption of the upstream sorbent portion. This concept allows the status to be determined independently of the filter history. Additional temperature and humidity sensors are integrated to compensate for the effects of boundary conditions. Furthermore, the extent to which the online evaluation of the humidity curves enables redundant breakthrough detection is being investigated.

An apparatus for the layer-by-layer investigation of activated carbon portions using laboratory measurement equipment has been developed and is used to analyze the adsorption front and the associated boundary conditions at different positions along the filter length. The concept development has been completed, prototypic sensor elements have been manufactured and tested both individually and on an adsorption filter. The functionality of the concept and the sensor elements was demonstrated in these laboratory tests with isopropanol as the pollutant. Current steps are the adjustment of the sensitive materials to other pollutants and the automated data acquisition by the evaluation unit for more extensive test series.

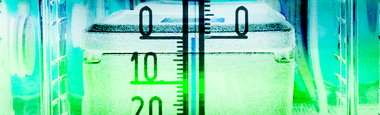

Figure 3: Correlation of the sensor signals with the local pollutant concentration during an activated carbon breakthrough in a laboratory test

Conclusion / Outlook

The future use of this technology will bring benefits for the enviroment, the people affected, industry and sociaty:

- cost savings for the operation of sorption filters/systems due to the complete utilization of the sorbent used,

- Ensuring environmental, personal and system protection from the pollutants to be filtered,

- Possibility of process monitoring and better planning of the required use / change of sorbents,

- Conservation of existing resources and chemical (partly fossil) raw materials.