You are here: Home / Measurements and Tests

State of system and failure analyses

Cause of the failure unknown?

We support the industry in the development of energy-efficient vapor-compression refrigeration system and compression heat pumps.

The ILK Dresden offers the following services for you:

The ILK Dresden has been active in the development and testing of refrigeration and heat pump technology for many years. A focal point of our activities is the condition analyses of refrigeration compressors and the damage analysis of refrigerating plants and heat pumps.

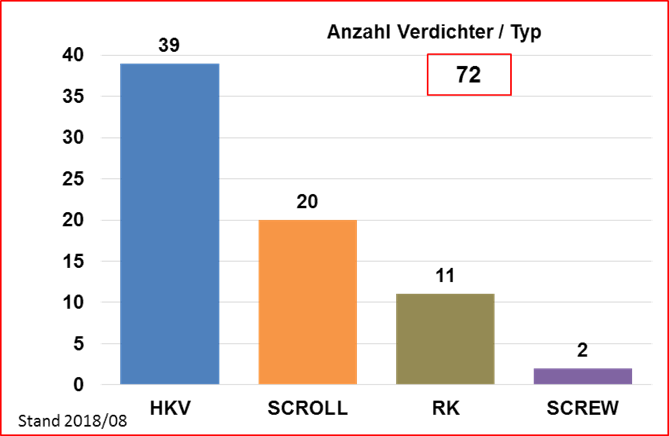

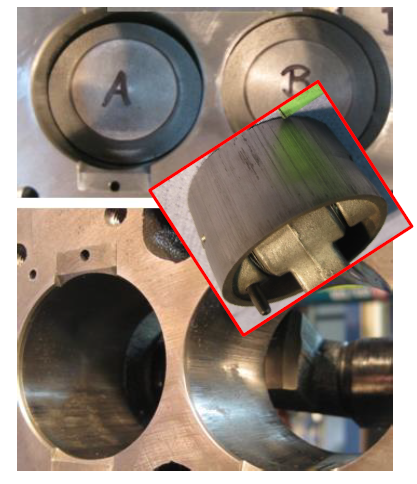

We can pass on our many years of experience in the analysis of different compressor types (Fig. 1) in suggestions and hints for further compressor operation and plant behavior (Fig. 2).

We can offer the following Services:

- Condition analysis of refrigeration compressors

- Evaluation of damage causes at the compressor

- Notes on further operation after sample analysis from the field

- Definition of lifetime test programs (500 h) with different stress levels inside and outside the compressor map (liquid, continuous switch, frequency, pressure ratio etc.)

- Implementation of these different test programs for the service life of the compressor type on a suitable test rig with subsequent analysis of the refrigerant compressor

Research and Development

The ILK Dresden has been active in the development and testing of refrigeration and heat pump technology for many years. The development work is carried out individually and in close cooperation with the client.

The ILK Dresden has many years of know-how in the investigation of refrigerant compressors.

The necessary know-how for the evaluation of the machines was developed in particular in the funded projects:

- "Energy efficiency of refrigerant compressors", (BMWi EN FKZ IW073034),

- "Multi intermediate injection at rotary compressors", (BMWi EN FKZ VF120022)

- "Procedures for compressor protection" (BMWi EN FKZ MF150165),

In these projects, knowledge was gained in particular on the following topics, which enable a professional interpretation of the results:

- Constructional design of different compressor designs

- Gradients for degree of quality and degree of output as function of compressor design and compressor map

- Knowledge about the behaviour of refrigerating capacity, power absorbed and COP depending on compressor design and operating conditions

- Relationships between external and internal conditions of the compaction process and effects on the definition of comparative parameters

- Evaluation of the operating condition-dependent behaviour of the refrigerant/oil mixture in the compressor housing of different compressor types (reciprocating and scroll compressors)

- Evaluation of the time migration of refrigerant into the compressor during thermally different downtimes