You are here: Home / Research and Development

Low Temperature Tribology

Tribological studies at cryogenic temperatures

For special applications at cryogenic temperatures the use of dry friction is necessary because the working temperatures are significant lower than the working range of liquid lubricants.

The ILK Dresden has extensive experience in the field of material testing at cryogenic temperatures and has developed a measuring system (from roomtemperature down to cryogenic temperatures) to determine the roughness and the coefficient of friction of different sliding material combinations.

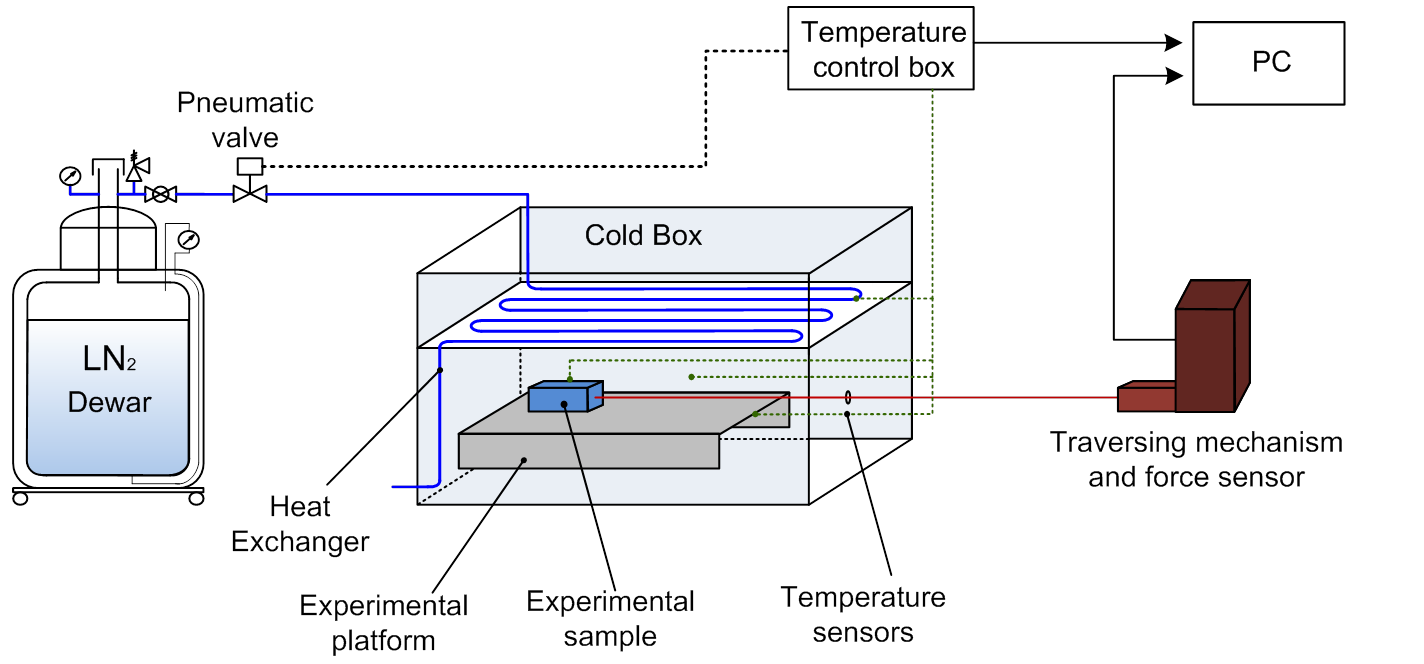

The test stand consists of an experimental platform and a traversing mechanism with a force sensor, which is controlled via PC. The direct measurement of the friction force is carried out by the distance covered. Measurements can be performed down to −196 °C (lower temperatures on request). The cooling of the experimental platform and the samples is realised by a controlled liquid nitrogen heat exchanger/evaporator. Measurements are performed under an atmosphere of gaseous nitrogen to prevent the ingress of moisture. Thereby the experimental samples have no direct contact to liquid nitrogen. The uniform temperature distribution is measured by thermocouples, which are calibrated at the ILK Dresden.

Advantages: modular test setup which can be changed to specific requirements; adjustment of sample geometry and/or test track is possible.

Parameter

| Measuring accuracy | Measuring range 0.4 N to 2 N | ≤ 1 % of measured value |

| Measuring range 2 N to 100 N | ≤ 0.5 % of measured value | |

| Measuring range extendible up to 5 kN | ||

Repeatability | ± 0.05 N respectively 1.5 % of coefficient of friction | |