Parts and components of machines such as satellites or space telescopes are subject to mechanical stress. In addition to the mechanical stress, the temperatures at which these components are used also have an influence on their strength and thus also on their lifetime. In the area of materials research, material aging and especially for space applications with the very high temperature changes that occur in a vacuum, temperature change tests are essential. These tests normally are combined with subsequent strength testing. With the knowledge gained, e.g. how the component strength changes due to extreme temperature changes, the components can be optimally designed with regard to the special requirements for reliability and minimum weight.

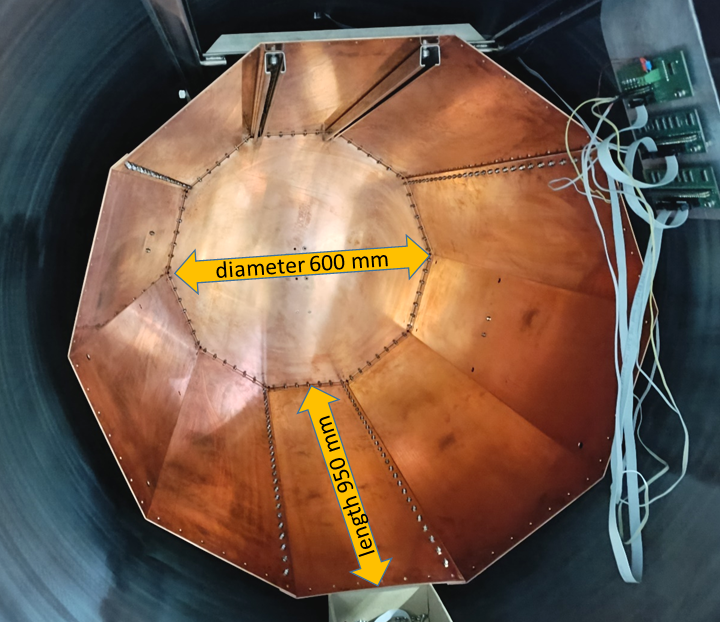

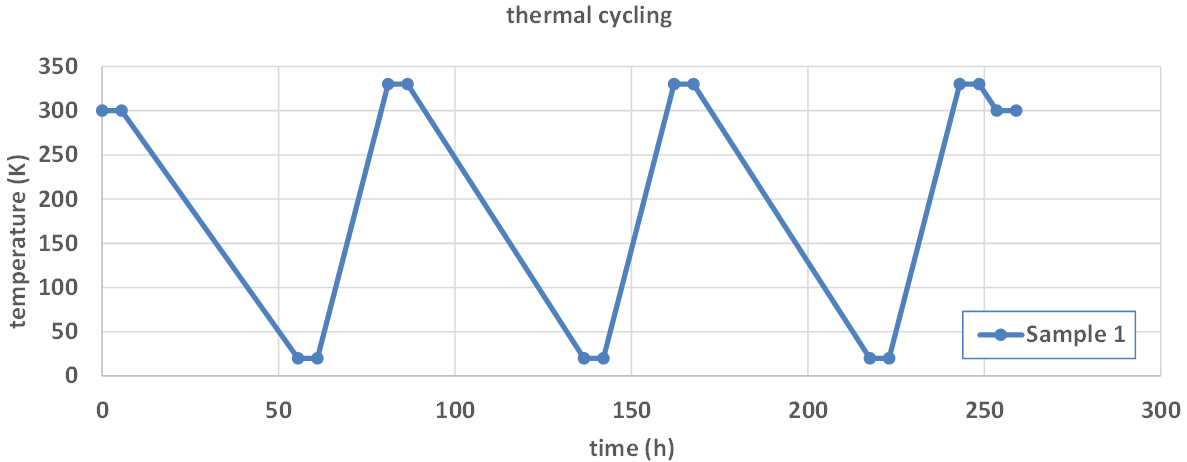

A test chamber has been build up at the ILK Dresden specifically for such temperature change tests. With the help of this thermal cycling chamber, parts or components can be exposed to changing temperatures for different durations. The temperatures can be specified in the range of 20 – 363 K for defined time intervals. The temperature gradients, performing the change from the lowest temperature to the highest temperature or reverse can also be specified in a range. Using a programmable electronic control, temperature profiles can be defined and run through in automated test operation over several hours to several days.

| Sample limits | Parameter |

|---|---|

| Temperature range | 20 K ... 363 K / -253°C ... +90°C / -423°F ... 194°F |

| Temperature stability | ± 1 K |

| Dimension, length x width | 0,95 m x 0,6 m / 3 ft x 2 ft |

| Mass | up to 30 kg / 66 lb |