You are here: / Home

Development of a Cryogenic Magnetic Air Separation Unit

Federal Ministry for Economic Affairs and Climate Action

02/2022-07/2024

Erik Neuber

+49-351-4081-5122

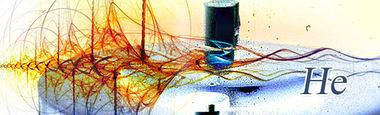

Oxygen Enrichment by Applied Cryogenic Magnetohydrodynamics

Nowadays, for oxygen enrichment from air, various commercial options are available, among other things, pressure swing adsorption, cryogenic rectification, and membranes. Although well-established, most of these methods do have a relative high specific energy demand for small-to-medium production rates (in this context: 0–100 TPD (tonnes per day) of oxygen) and relative high purities (at least 90 vol% of oxygen) [1].

To close this gap, ILK Dresden intends to develop and optimise an efficient cryogenic magnetic air separation unit that enables oxygen enrichment by means of OGMS (open-gradient magnetic separation). Motivated by provisional first-shot experiments, for a first setup, the following parameters are being targeted:

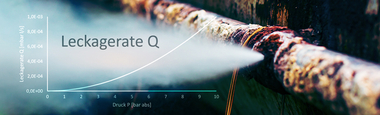

- Operating pressure: 1–3 bar(a);

- Degree of purity: 95 vol% oxygen;

- Production rate: 5 standard l/min oxygen;

- Specific energy demand: 160–180 kWh/t oxygen;

- Required time for start-up: 30–60 min;

- Continuous operation;

- Less maintenance requirements than pressure swing adsorption;

- Comparable space requirements as pressure swing adsorption.

Moreover, based on the experimental results, the scalability of the system for higher production rates of up to 100 TPD oxygen shall be analysed.

For this patented technology, ILK Dresden is looking for industrial partners that have interest in financial participation, specific applications, or further developments.

Granted Patent:

DE 10 2021 109 146 A1