You are here: Home / Research and Development

Calibration of Low Temperature Sensors

According to the comparative measurement method

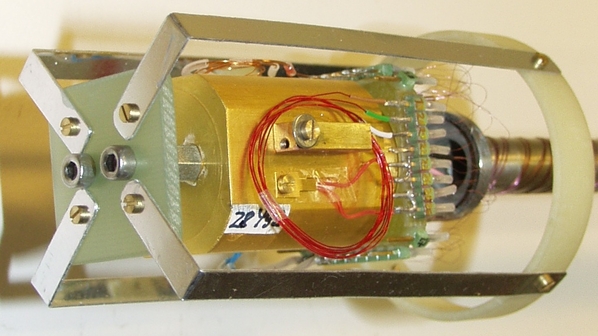

Accurate and reliable measurements are the requirements for high-quality research and development or industrial production. Using the comparative measurement method the following sensors can be calibrated:

- Resistance Temperature Detectors (RTD) with positive temperature coefficient (like Platinum or Rhodium-Iron RTDs)

- RTD with negative temperature coefficient (like Germanium or Cernox™ RTDs)

- Diode and thermocouples.

With an automatic measuring station several temperatures according to a sample point table will be adjusted. The calibration is carried out with secondary thermometers that are calibrated by an authority. Furthermore a fix point check with LHe or LN2 will be performed. In addition, a calbriated Cernox sensor is available for measurements in the low temperature range. The measuring facility allows the calibration of about 30 sensors at once. There are continuous extensions for different sensor types.

Parameter

| Indicator | Minimal | Maximal |

|---|---|---|

| Measuring range | 1.5 K | 350 K |

| Measuring accuracy | 5 mK (1.5 ... 4.2 K) | 50 mK (80 ... 350 K) |

| Sample dimension | common sensor packages | |

| Sample preparation | not necessary |

Your Request

Further Projects - Research and Development

All-in-one device for freeze-drying and production of biomaterial

with automated freezing and sterilisation option