You are here: / Home

Preformance measurements of heat exchangers

Is the heat exchanger properly sized?

We support the industry to improve the efficiency of components for cooling systems and heat pumps.

The ILK Dresden offers the following services:

We determine the preformance and pressure losses of plate heat exchangers (evaporators and condensors) or other heat exchangers for liquids in a defined range.

The measurment is based on the following norms

- DIN EN 306 Heat exchangers - Methods of measuring the parameters necessary for establishing the performance

- DIN EN 1117 Heat exchangers - Liquid cooled refrigerant condensors - Test procedures for establishing the performance

- DIN EN 1118 Heat exchangers - Refrigerant cooled liquid coolers - Test procedure for establishing the performance

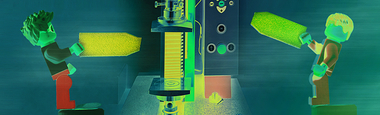

The test are preformed at a special developed test rig, which can be seen on the following picture.

Operation range of the test rig

- Kältemittel: Refrigerants: R134a, R404a, R407C, R410A, R507, (others on request)

- Coolant: Brine

- Heat carrier: Water

- Maximum Performance condensor: 70 kW

- Maximum Performance evaporator: 60 kW

The measurement systems are calibrated regularly.

Additional services

We can support you at following tasks

- Technical design of components

- Optimisation of components

- Software development for technical design and optimisation

Also we can offer you

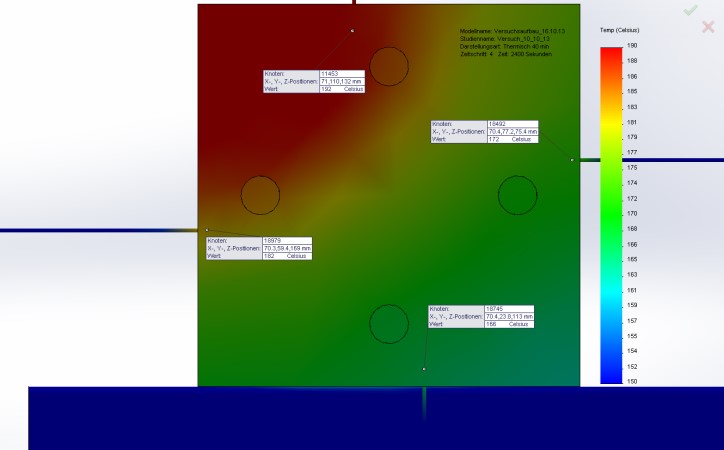

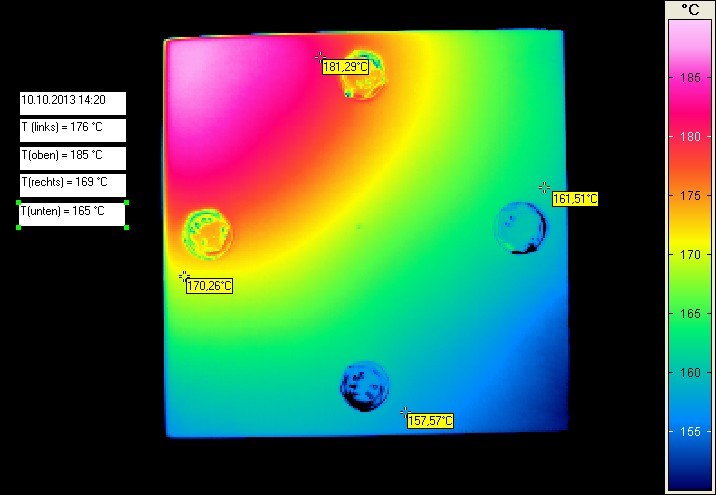

- static and time-varying thermal simulations

- thermography of components

The ILK Dresden has many expertise and a high flexibility in the field of air and refrigeration technology. You will benefit from the broad spectrum of our research directions and technologies as well as the integration of various fields of expertise.

Your Request

Further Projects

Hydrogen and methane testing field at the ILK

Simultaneously pressures up to 1,000 bar, temperatures down to –253°C

Low noise and non metallic liquid-helium cryostat

Low-noise Magnetic Field Cryostat for SQUID-Applications