You are here: / Home

ZeroHeatPump

Performance management of small heat pumps without energy consumption

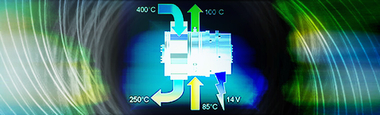

The combination of small photovoltaic systems (balcony power plants) through intelligent power management with small heat pumps including optimised partial load control represents a rapidly effective contribution to the implementation of the energy transition in Europe. Different output ranges of the balcony power plants with outputs of 600/800/1200W are being developed as part of this process development with adapted partial load control as a supplement to existing heating systems as targeted heat and cooling generators with the aim of optimising zero energy consumption. The use of efficient inverter compressor drive variation is being implemented, taking into account maximum operating limits. The range from integrated software solutions to system-independent software and hardware extensions is focussed on applications in both private and commercial heating and cooling technology. The independent separate utilisation of the balcony power plant and small heat pump inevitably leads to considerable differences between generator output and consumer. The aim of this project is to achieve an optimum balance. Continuous partial load control is used to fine-tune the difference to zero.

Project aim

The aim of this project is to develop a process for optimising the performance of small heat pumps with virtually no external grid energy consumption in existing homes.

Efficient processes for the customised power management of small heat pumps with partial load control are to be investigated and developed. The focus here is on heat pump operation that is as continuous as possible based on the self-generated grid feed-in power from inverters of balcony power plants.

Solution approach and development steps

The process development of an intelligent workspace expander is one solution. The largest electrical consumer within the heat pump is the compressor. The energy-efficient speed control for partial load management on the compressor, especially up to the lower operating limit in heating and cooling mode, is analysed for this purpose.

- Power classes of the energy source 600W/800W/1200W

- Determination of the lower operating limit for heating and cooling

- Determination of the most efficient use and combination variants

- Cost comparison of different variants

- Analysis of inverter control methods for partial load and wide range optimisation

- Investigations of possible control strategies with/without (electrical) storage Process development software

- Process development hardware-software combination

Results of the project

The result will be process variants with software and hardware solutions that enable heat and cold conversions with little or no external grid energy consumption.