You are here: Home / Software Development

Reducing the filling quantity

How much refrigerant must be filled?

Due to the F-gas regulation of the EU, synthetic refrigerants are becoming increasingly expensive and more difficult to obtain. The synthetic and partly natural substitute refrigerants are often flammable or toxic. The remaining synthetic refrigerants with low hazard potential are becoming more and more expensive and some of them still have a significant global warming potential. For this reason, it makes sense to keep the filling quantity of all new refrigeration systems as low as possible. Historically, refrigeration plants have usually been built without much consideration for the filling quantity of the plant. Often even large collectors were installed in order to always have a sufficient filling quantity without exact calculation and to compensate for the loss of refrigerant between the service intervals.

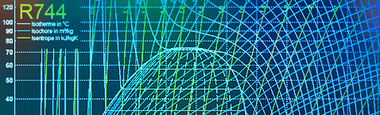

In this project, possible actions are investigated, which lead to significant reductions in refrigerant filling quantities already in the design and construction phase. In particular, the necessity and size of refrigerant receivers will be investigated. Except for a refrigerant receiver, the largest refrigerant quantities are found in the heat exchangers of the refrigeration cycle, i.e. in the condenser up to 50 % (according to other literature sources even up to 65 %) and in the evaporator up to 25 %. As a result, very strong levers for reducing the refrigerant charge can be seen in these components. Therefore, the necessary filling quantity of different heat exchangers should be examined and measured in detail. Thereby classical tube-fin, microchannel and plate heat exchangers shall be investigated.

As a result of the project, a new method is to be developed which takes into account a maximum possible reduction of the refrigerant charge quantity from the outset when planning and designing a refrigeration system.

Based on the first results and previous experience we can offer calculations of the filling quantity. Furthermore, a program for calculating the filling quantity is in preparation.