Project management: Dr. Franziska Krahl, Dr. Steffen Feja

Unlike electrically driven compression chillers or compression heat pumps, ammonia absorption systems (chillers and heat pumps) are driven by thermal energy. If the thermal energy comes from solar thermal energy, geothermal energy or waste heat, for example, these machines can be operated without fossil fuels. The working substances water and ammonia used are naturally occurring compounds, do not contribute to global warming (GWP = 0) and also have no ozone depletion potential (ODP).

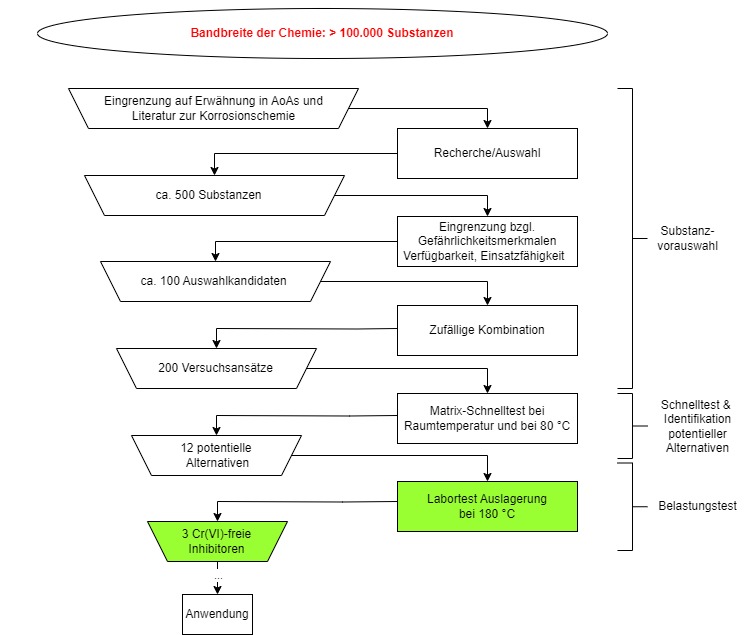

The research project focused on identifying a suitable corrosion inhibitor for ammonia absorption systems to replace chromium(VI) compounds. A strategy was developed to enable the investigation of a large number of potential alternatives. From a total of more than 200 substance combinations (test approaches), 12 promising alternatives for further laboratory tests were identified using a rapid test developed in the project.

The rapid test developed proved to be very efficient in terms of identifying potential corrosion inhibitors. By using sealed reaction chambers, this test can also be carried out at significantly higher temperatures, which means that conditions close to the application are already present during screening.

At the end of the research project, 3 chromium(VI)-free corrosion inhibitors for ammonia absorption systems will be available, the basic suitability of which has been proven in laboratory tests. Their effectiveness is now to be tested in demonstrators.