You are here: / Home

Cold meter

The fast way to refrigerating capacity

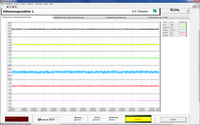

The ILK Dresden offers you special cold meters to determine the exact cooling capacity of your refrigeration system. These consist of a mass flow sensor, pressure sensors, temperature sensors and a suitable measured value acquisition. The associated software stores and analyses the measured values. The evaluation provides clear diagrams and key figures. Of course, the systems are calibrated before commissioning and can also be recalibrated.

Specification

- refrigeration capacity range: ~ 0,5 kW … 300 kW (other ranges on request)

- all common refrigerants

- mass flow measurement is operating with the principle of a Coriolis flow meter

- measurement of temperature and pressure in the refrigeration cycle

- calculation of the refrigeration capacity from material properties using Reflib of the ILKs

- comfortable evaluation and calculation software

- monitoring of different parameters

- hardware monitoring of measuring channels and network connection

- error analysis