You are here: / Home

Humidifier System for High-Purity Gases

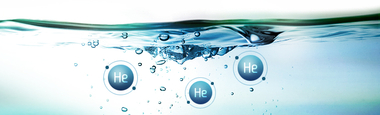

Nafion - moisture transfer

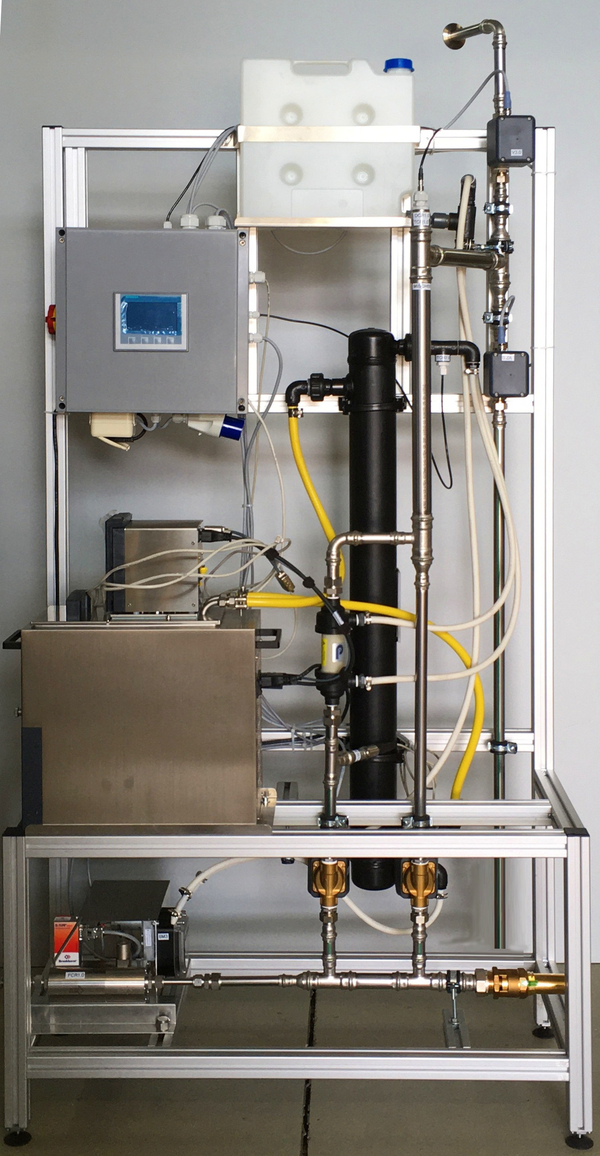

At the ILK Dresden a humidification system was developed and manufactured which is especially suitable for research facilities where very low dew point temperatures have to be adjusted and at the same time a high gas purity has to be guaranteed. The core component is a PermaPure® humidifier with Nafion® moisture exchange. The humidification system precisely controls the dew point via a bypass mixing with dry gas and also takes over the automatic filling of evacuated containers. The control system is optimised to prevent recondensation. Humidification can be controlled from any plant system via an interface. Table 1 shows the technical data of a humidification system for the humidification of synthetic air realized for the KIT in Karlsruhe. The system can be adapted for other applications, and all parameters can be adjusted to the respective requirements.

| Parameter | Value |

|---|---|

| setpoint gas flow | 750 litre/min |

| maximum relative humidity | 95% |

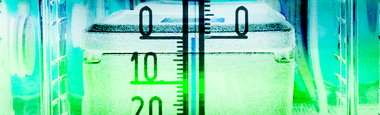

| minimum dew point | -60°C / -76°F |

| degree of gas purity | 5.0 |

| gas purity, number of particle | < 5 particle/cm³ |

Your Request

Further Projects

Reduction of primary noise sources of fans

...using numerical and experimental methods with contra-rotating axial fan

Software for technical building equipment

Design cooling load and energetic annual simulation (VDI 2078, VDI 6007, VDI 6020)