You are here: Home / Research and Development

In-situ investigation concerning the swelling behaviour of polymer materials under elevated pressures and temperatures

Material Science

Polymerwerkstoffe sind heute nicht nur im Alltag, sondern auch im technischen Einsatz nicht mehr wegzudenken. Neben den klassischen Konstruktionskunststoffen spielen im Bereich der Kältetechnik vor allem Elastomere in Form von Dichtungen eine Rolle. Die grundlegenden Werkstoffeigenschaften sowie eine gleichbleibende Qualität des Materials sind hier entscheidend für den störungsfreien Langzeitbetrieb der Anlagen und für die Vermeidung von Kältemittelverlusten.

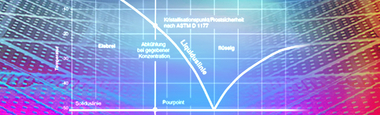

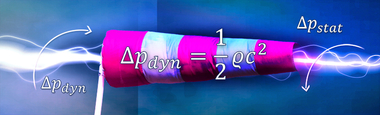

Ein Indikator für ihre Medienbeständigkeit und somit ein wichtiger Parameter für den Einsatz der Werkstoffe ist das Quellverhalten der Polymere im Kontakt mit flüssigem bzw. gasförmigem Kältemittel (und mit Kältemaschinenöl). Bisher war eine Prüfung bzgl. der Veränderung der Polymere durch die Lagerung unter erhöhten Gasdrücken erst nach deren Entnahme aus dem Medium, also erst NACH der Dekompressionsphase, möglich. Für das in der Praxis relevante Verhalten der Materialien WÄHREND der Medienbelastung und Dekompression waren die Daten bisher nur bedingt aussagekräftig. Genau hier setzt das neue In-Situ-Messverfahren an.

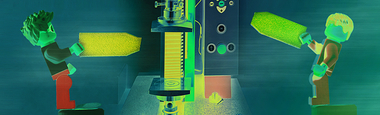

The objective of the research project is to develop and set up a suitable test method for measuring the swelling or shrinkage process of polymer materials in situ under process conditions, i.e. during chemical and mechanical stress (p-T). Utilizing a see-through autoclave, a measurement system is to be configured that can be used for investigations in a temperature range up to 80 °C and for pressures up to 90 bar. Two alternative optical measurement methods will be used and compared. The first is a camera system for recording and measuring the time-dependent swelling behaviour of the samples. The second system is a high-speed 2D optical micrometer.

The measurement method should allow a time- and cost-saving evaluation of materials and provide a basis for the development of improved sealing materials. Thus, this research project contributes significantly to improving product sustainability and the safety of refrigeration systems.

The ILK is the leading institute for method development and investigations on material behaviour in the field of refrigeration technology. With the in-situ method, the existing test methods in the field of material aging and evaluation are supplemented by an innovative measurement procedure.