Within the research project "Mobile single-stage pulse tube cooler with hermetic compressor drive" (project number MF 130012), a compact, robust and low-maintenance cryocooler was developed.

Possible applications for this cryocooler, e.g.,

- Cooling of mobile high-pressure tanks for storing fuels in cryogenic liquid or supercritical state (e. g. H2 – cryogenic under high pressure)

- mobile cooling applications < –40°C in medical technology, transport of organic material or samples

The system has a simple and cost-effective design with the following advantages:

- Mobile use, supply voltage 12 V or 24 V, air-cooled

- Supply of cryogenic temperatures in the range 60...120 K

- Low maintenance and long-life, no moving parts in the cold part

- Programmable temperature curves via microcontroller-based control

- Low power consumption, in the range of 500 W

- Low space requirement, arrangement can be adapted

- Lower costs control through extensive use of commercial components

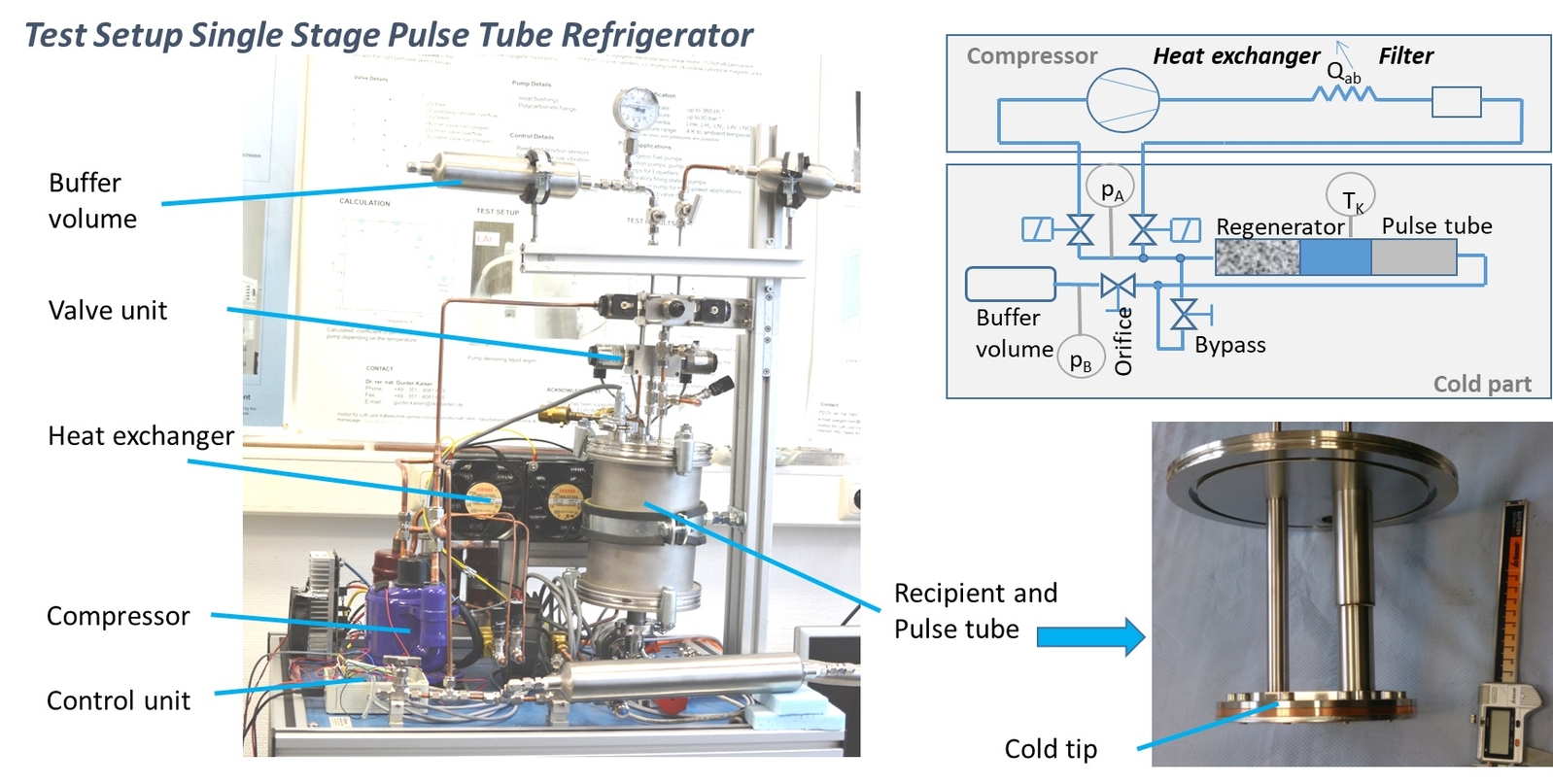

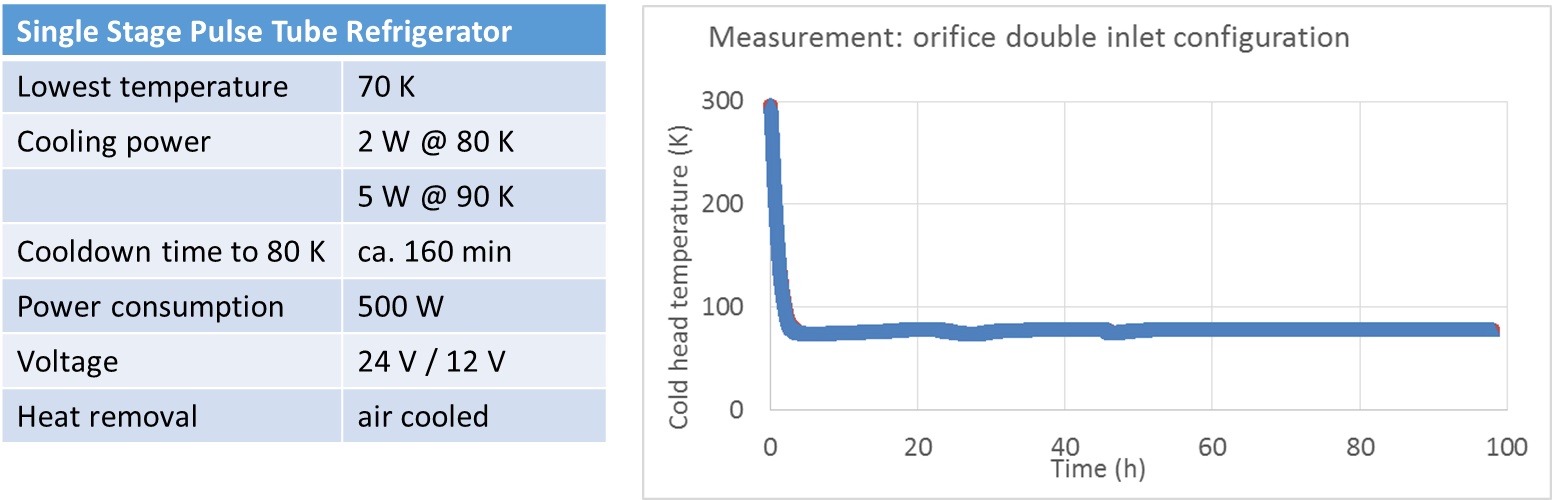

Figure 1 shows the experimental setup of the cryocooler in a specially adapted orifice double inlet configuration. With the use of a special valve control, 2 W cooling capacity at 77 K and 5 W at 90 K could be achieved. The lowest temperature reached with this single-stage configuration was 68 K. The temperature stability of the system was validated in a test lasting 100 h, see figure 2. In further investigations with a specially adapted compressor, even lower temperatures are to be achieved, down to 40 K.

We are looking for industrial partners for adaptations for special application purposes or possible further developments. Conceivable are, for example, a compact system suitable for use in motor vehicles in a functional housing with the necessary interfaces or a further development of the current cooler to achieve higher cooling capacity, lower temperatures and higher efficiency.