You are here: / Home

Panel with indirect evaporative cooling via membrane

Natural Cooling Panel

Development of a decentralised cooling panel with outdoor air connection, without refrigerant, without humidity input into the room air, retrofittable and with coefficients of performance (COP) > 10

Motivation

- GWP = 0; COP > 10; 100% renewable energy

- Decentralised indirect evaporative cooling with no moisture in the indoor or outdoor air

- Self-sufficient operation, rainwater harvesting

- Radiant and convective air discharge

Project Objective

- Application of regenerative and sustainable cooling via evaporative cooling in a decentralised air conditioning system (COP > 10)

- Functional combination of evaporative cooling and supply of purified outdoor air

- Novel membrane heat exchanger for two air streams and evaporation water including numerical calculation model

- Novel convection and radiation efficient air outlet for minimum draught risk

- Modular, cascadable unit concept for on-demand performance and off-grid and CO2-neutral operation (for PV power supply)

- Ceiling-mounted, wall-mounted or free-standing cooling panels for residential and non-residential buildings, retrofittable and acoustically compliant

Solution Approach

- Development of a membrane heat exchanger based on 4-layer textile laminates

- Development of equipment based on supply air recirculation and exhaust air humidification processes

- Development of an air outlet for convection and radiation cooling performance

- MSR and system components for rainwater harvesting, site-independence and cascading

Further Projects

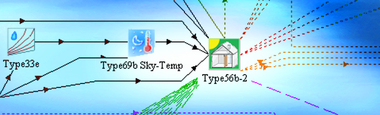

Combined building and system simulation

Scientific analysis of thermodynamic processes in buildings and its systems

Development of test methods and test rigs for stationary integrated refrigeration units

How efficient is my refrigeration unit?