You are here: Home / Research and Development

Innovative Parahydrogen Generator Based on Magnets

Magnetic Gas Separation of the Hydrogen Isomers

Molecular hydrogen occurs in two isomeric forms which differ in their configuration of the nuclear spin: orthohydrogen and parahydrogen, whereas the latter accounts for only 25% of the whole gas at room temperature. Contrary to this, parahydrogen in its concentrated form is utilised especially for hyperpolarisation (so-called PHIP – Parahydrogen Induced Polarisation), which is a widespread method in the fields of medicine and chemistry to enhance the contrast of MRI and NMR apparatus.

However, all procedures for the production of this spin isomer are based upon cryogenic methods, which have comparatively high expenses for energy and maintenance. Because of this, there exists the demand for a cheap and efficient method to enrich parahydrogen for direct use in successive applications.

Project Goals

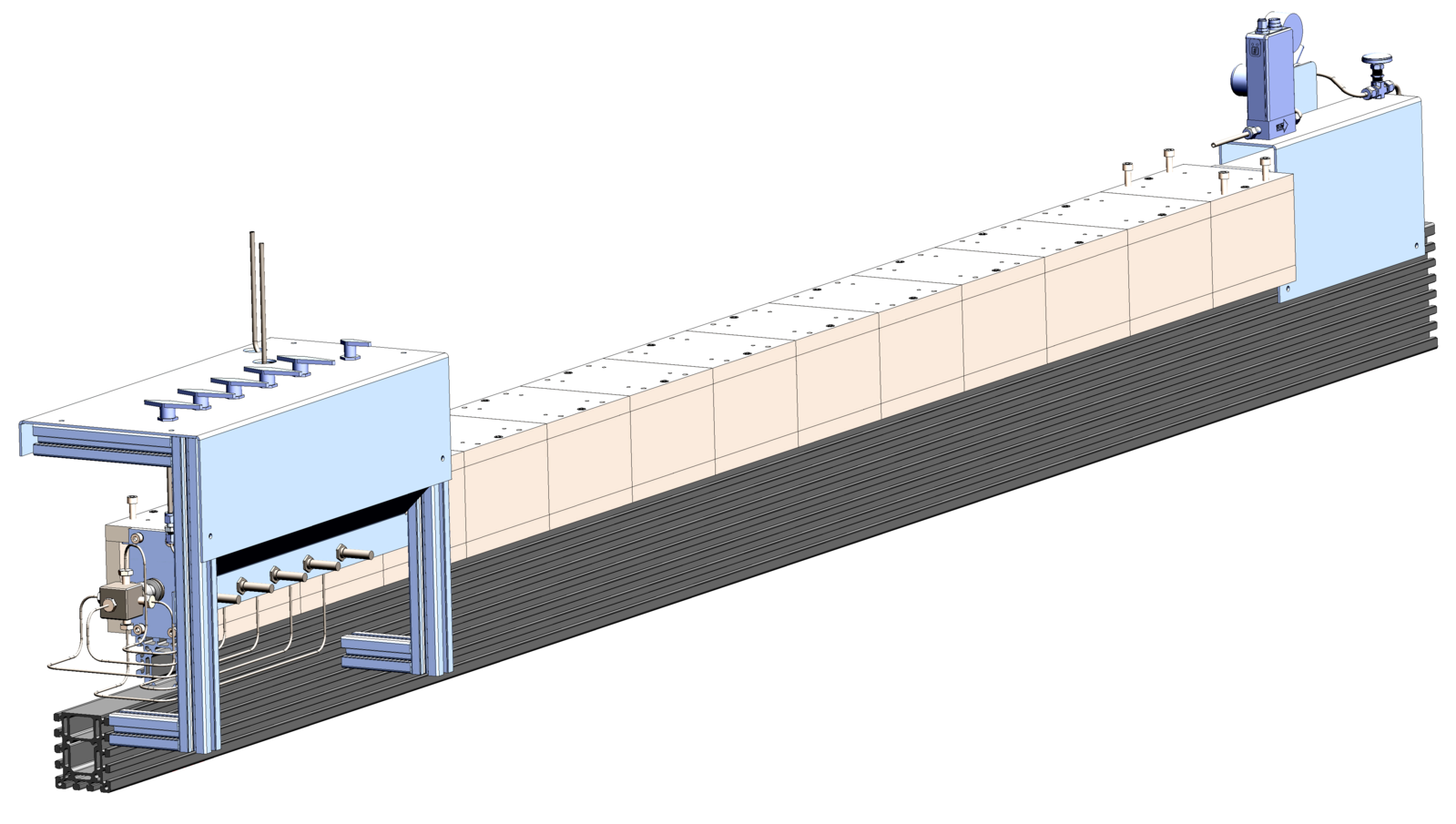

- Development of an innovative ortho–para converter, which works at room temperature by using the principle of magnetic gas separation;

- Measurement of the separation ability of the chosen principle at room temperature and optimisation of the resulting effect and

- Enrichment up to 99% of parahydrogen at a variable volume flow (pursued are at least 4 standard litres per minute).

Further Projects - Research and Development

Hydrogen and methane testing field at the ILK

Simultaneously pressures up to 1,000 bar, temperatures down to –253°C

Low noise and non metallic liquid-helium cryostat

Low-noise Magnetic Field Cryostat for SQUID-Applications

Cryostats, Non-Metallic and Metallic

position indenpendent, highest endurance, tiltable for liquid helium and liquid nitrogen

Cryogenic liquid piston pumps for cold liquefied gases like LIN, LOX, LHe, LH2, LNG, LAr

Feeding pumps for cryogenic liquid gases